Thin Metal Foil Thermal Straps

(TMF Series™)

Our TMF Series™ Thermal Straps include both Copper Foil Straps (CuFS™) and Aluminum Foil Straps (AlFS™). These thermal straps (thermal links, thermal shunts, or heat straps) can provide superior thermal and mechanical performance in many applications while at the same time offering the most volume efficient and contamination resistant packaging possible.

CuFS™ – Copper Foil Straps: ETP, OFHC, 5N Purity

Our CuFS™ are made from either ETP (C110), OFHC (C101, 4N purity), very-high 5N purity, and in rare cases 6N ultra-purity copper foil, depending on the application and need for thermal efficiency at low temperature. In most applications, we recommend ETP copper foil thermal straps for temperatures above 40 K and OFHC copper foil thermal straps for use below 40 K. While ETP foil is more common, less expensive, and readily available, OFHC copper foil straps can also be fabricated on a relatively short schedule. For higher purity CuFS™, please contact us about the timeline to support a specific thermal strap application.

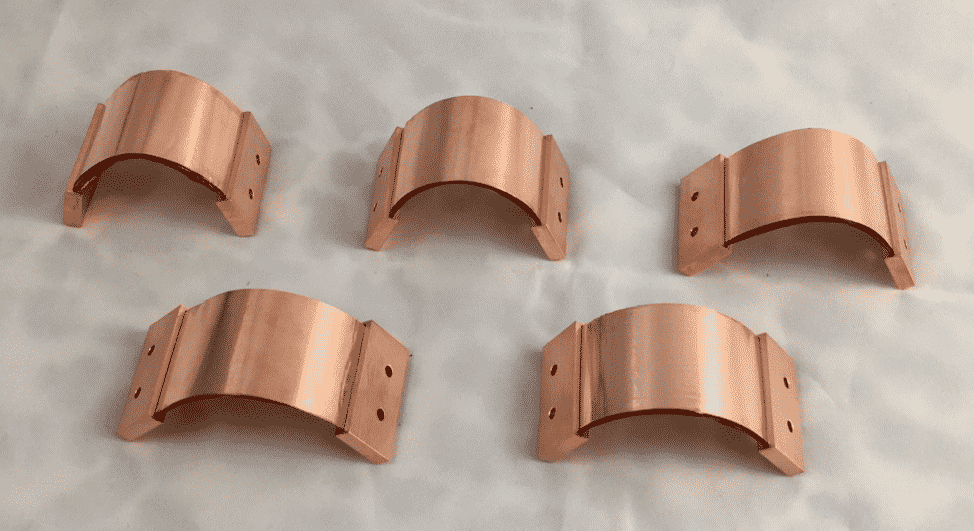

High-Purity Cu Foil Strap with 3D Curvature

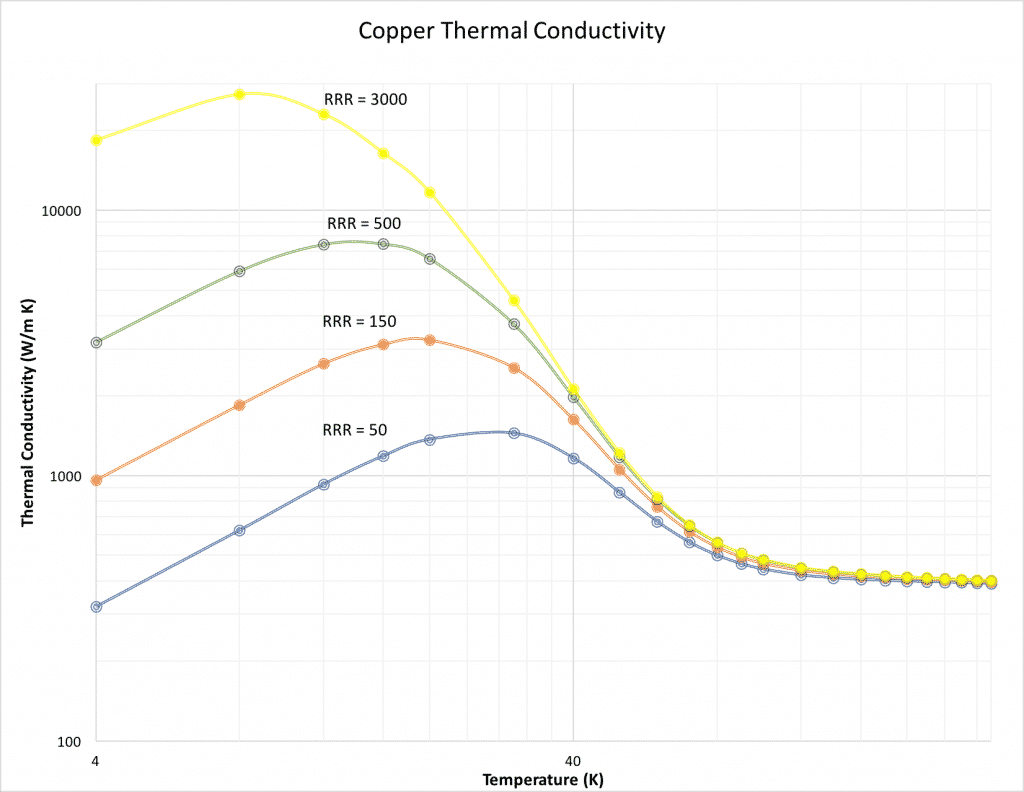

Copper Purity and RRR

The table shows the range of residual resistivity ratio (RRR) typical of the copper purity level. Temperature dependent thermal conductivity is much more accurately represented by RRR than just the material purity itself. Thermal strap construction from 5N and 6N copper can provide far superior performance at temperatures below 25 K, but there is an increasing material cost difference with the higher purities . When extreme low-temperature thermal conductivity is necessary, highly specialized 6N copper thermal straps can be fabricated, but only in smaller sizes due to very limited availability of the foil.

| Copper Type/Purity | RRR Range |

|---|---|

| Electrical Tough Pitch (ETP), C110/99.9% | 50-100 |

| Oxygen Free High Conductivity (OFHC), C101/99.99% | 100-500 |

| 4N/99.99% | 500-2,000 |

| 5N/99.999% | 1,000-10,000 |

The graph below shows the temperature dependent thermal conductivity for copper of various RRR. Note that a specific copper purity level can have a broad range for RRR. There are many reasons for this. Our engineers have experience and expertise in cryogenic and thermal material properties and can explain the factors that influence RRR (and thus thermal conductivity) and work with you to achieve optimum results in your application.

CuFS™, when fabricated from either ETP and OFHC copper foils, can be configured up to several feet in length and nearly any practical width and cross-section. Individual foil thickness can be varied to achieve the optimum combination of thermal conductance, mechanical flexibility, and cost for each individual application.

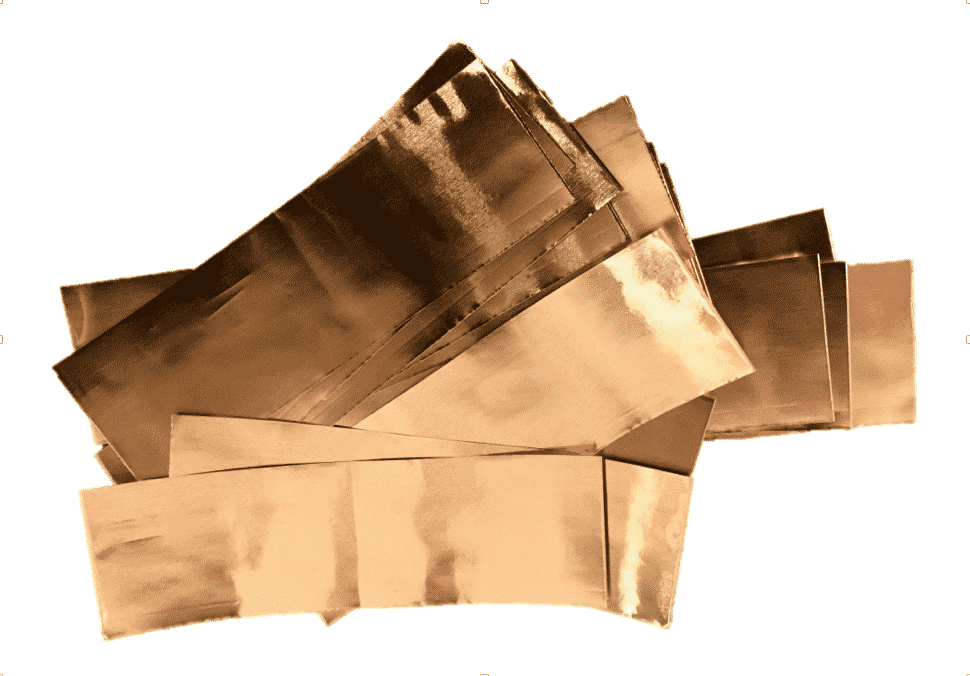

Cut OFHC (C101) Copper Foils

OFHC Copper Foil Thermal Straps for use in high vacuum.

Metallization

Any of our copper foil straps can be gold coated using a specialized process that provides the highest level of thermal control in some environments and passivates all surfaces for oxidation mitigation.

Important Note: The metal coating process we use is very different from generic plating that can cause a host of issues in thermal straps.

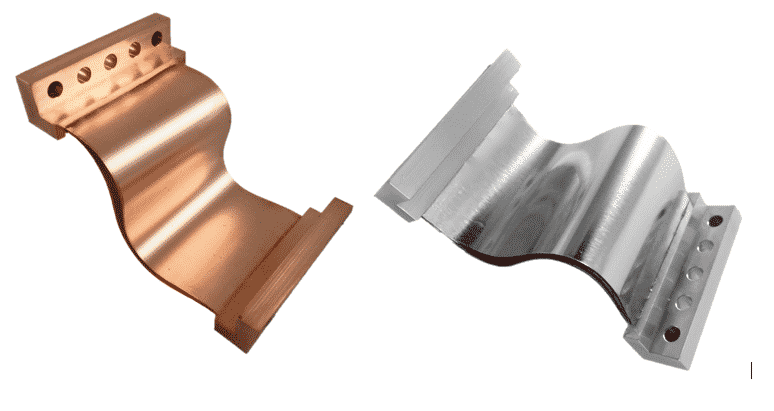

AlFS™ – Aluminum Foils Straps: 1100, 3N, 4N, 5N Purity

AlFS™ are made from aluminum foil and end fittings in purity ranging from 99% (Al1100) to 99.999% (5N). For most applications, 1100 aluminum will provide the thermal conductance required in the temperature range of interest. For low-temperature applications, the higher purity options are often attractive. Aluminum straps are typically the choice over copper in mass-limited thermal management applications because even though aluminum thermal conductivity is less than copper, aluminum has roughly one third the density of copper.

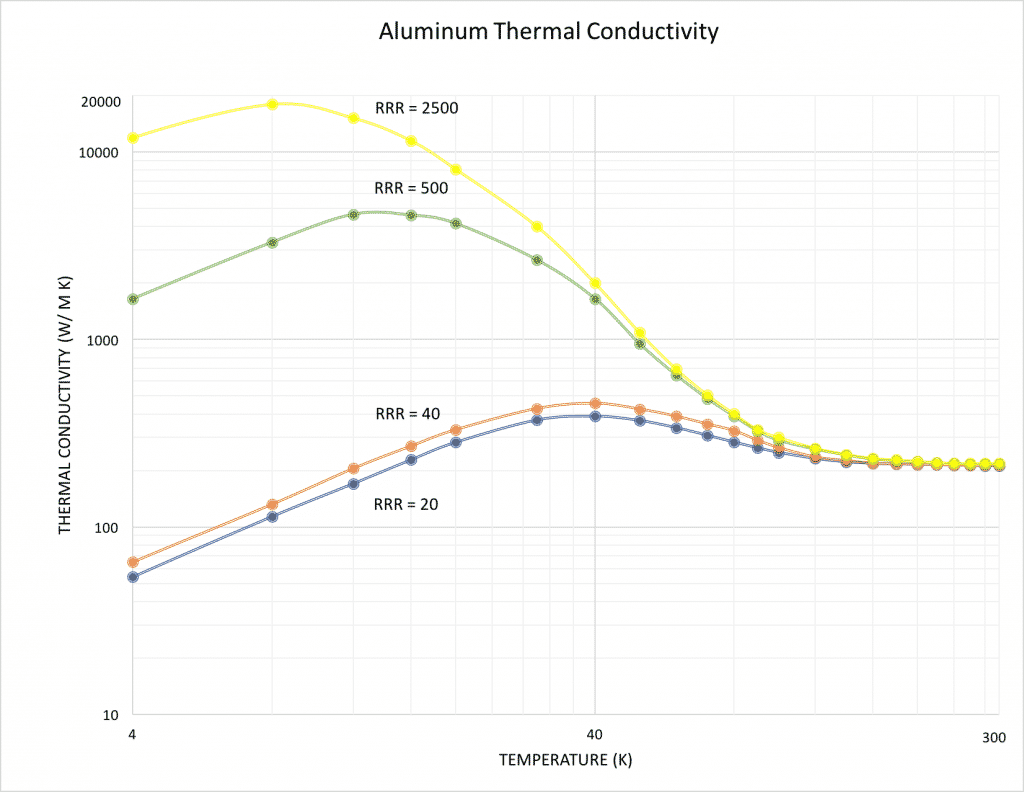

Aluminum Purity and RRR

The table shows the range of RRR typical of the aluminum purity level. As in copper, the thermal conductivity of aluminum improves significantly at lower temperature with the higher RRR value material. However, with aluminum the improvement becomes apparent at a higher temperature of 70 K. In fact, higher purity aluminum becomes even more attractive than similar purity copper on a thermal conductivity to mass basis for use in the temperature range below 70 K.

| AluminumType/Purity | RRR Range |

|---|---|

| 1100/99% | 10-50 |

| 1050/99.5% | 20-80 |

| 3N/99.9% | 35-105 |

| 4N/99.99% | 100-5,000 |

| 5N/99.999% | 150-10,000 |

Our standard AlFS™are constructed from Al 1100 and can be fabricated in dimensions from less than an inch up to several feet in both width and length. As with CuFS™, foil thickness can be selected to achieve the optimum combination of thermal conductance, flexibility, and cost. In higher purity, aluminum foil thermal straps are available with a slightly longer lead time.

Metallization and Interfacing

With aluminum thermal straps, thermal interfacing techniques can differ from either copper or carbon thermal straps to achieve the most efficient performance. We have many years of experience with the application of metal films and the use of thermal interface materials to enhance the thermal conductance across aluminum interfaces all the way down into the extreme cryogenic temperature range. Our engineering team will work with you to not only provide the optimum thermal straps, but to also assure that your thermal system will not be compromised by excessive thermal interface resistance.