Cryogenics and Thermal Management Solutions

Headquartered in Boulder, Colorado, Thermal Space Ltd. is an independent and solely US-based company.

We provide comprehensive and complete cryogenic and thermal-management engineering and hardware solutions that can involve the simplest components such as thermal straps or heat pipes to complex state-of-the-art cryostats and custom cooling systems.

Passive and active thermal engineering technologies that we have been involved with and utilize on a regular basis to provide integrated thermal management system solutions include:

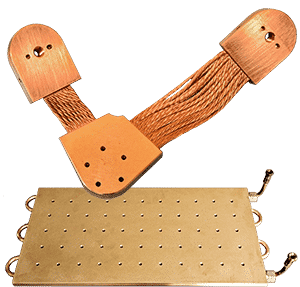

Thermal straps built from either copper cable (bundled copper wires), copper foil, aluminum foil or ultra-high conductivity graphite or graphene-based materials.

Thermal straps built from either copper cable (bundled copper wires), copper foil, aluminum foil or ultra-high conductivity graphite or graphene-based materials.- Heat pipes and vapor chambers that can operate between elevated and cryogenic temperatures. We also integrate our thermal straps directly with heat pipes and vapor chambers when there is the combined need to move heat long distances with some mechanical flexibility.

- Thermoelectric coolers (Peltier devices) that can provide solid state cooling down to about 200 K.

- Vapor compression (J-T) refrigerators that utilize many different refrigerants and have the capability for cooling into the cryogenic temperature range.

- Regenerative and recuperative mechanical cryocoolers that are commonly used in space instrument systems.

- Cross- and counter-flow heat exchangers commonly used to minimize cold-stage loads.

- Phase-change materials (PCM) and heat exchangers for load-leveling in transient thermal dissipation applications.

- Flexible and distributed cryogenic cooling loops for remote and broad area cooling.

- Advanced insulations systems involving multi-layer insulation (MLI), glass microspheres, and/or high-vacuum.

- Vacuum insulated lightweight cryogen tanks.

Those thermal components and subsystems that are identified in blue text, we custom fabricate in house. The others we acquire from our close network of suppliers and partners. We can combine many of these components or subsystems for use in any integrated thermal-management system.

Our Customers

We take our profession very seriously and want our customers to engage us in each and every aspect that draws from our experience and knowledge base in thermal and cryogenic engineering. Every product that we either manufacture or procure, and that goes into to any thermal subsystem that we are responsible for, will meet or exceed our customer specifications. Our engineering team has an average of twenty-two years thermal engineering experience and has provided hardware or engineering services to the companies and organizations listed below in addition to many others.

NASA Boeing Honeywell MIT/Lincoln Labs

JAXA Lockheed Martin Ball Aerospace Sandia National Labs

ESA Raytheon BAE Systems Department of Energy

CSA Northrop Grumman Harris Corporation Department of Defense

Quality Management System

Whatever you’re doing, one small weakness can cause a costly failure – in money, time and lost production. A loose screw, a material unable to resist the heat or poorly fitted parts wearing each other out – it all comes down to quality. Is your system engineered for the most accurate precision? Is it made from the best raw materials to stand the test of environmental stress over time?

TSL’s quality management system (QMS) was written to conform to AS9100 rev C.

We have many years of experience administering aerospace QMS controls, including internal audits, management review and customer audits. In all cases, our QMS has been found to be compliant with and responsive to our customer requirements. Having staff directly experienced with aerospace quality standards allows us to quickly assess, adapt and conform to organizational specific approaches to quality. We understand quality is an integral part of any engineered product.