You Can Bookmark This Page Directly at www.SpaceStraps.com

The Most Advanced Solid-State Thermal Strap Solution Available

Graphene Thermal LyNX® Technology

Thermal Space Ltd. developed Thermal LyNX® to provide the most weight efficient, robust, and flexible carbon-based thermal strap technology available in the market today. The Thermal LyNX® brand name represents the Layered Nanostructured Cross(X)-Linked graphene material that is at the core of this state-of-the-art thermal strap technology.

Thermal Space Ltd. developed Thermal LyNX® to provide the most weight efficient, robust, and flexible carbon-based thermal strap technology available in the market today. The Thermal LyNX® brand name represents the Layered Nanostructured Cross(X)-Linked graphene material that is at the core of this state-of-the-art thermal strap technology.

Verified For Use in Space

Not to be confused with the delicate pyrolytic graphite sheet (PGS) or graphene composite or sheet materials advertised elsewhere as being extremely fragile and prone to failure, Thermal LyNX® is both robust enough to meet any demanding application while at the same time having far superior thermal performance and orders of magnitude higher flexibility than any other carbon or graphite fiber thermal strap.

Ultimate Aerospace Thermal Strap Solution

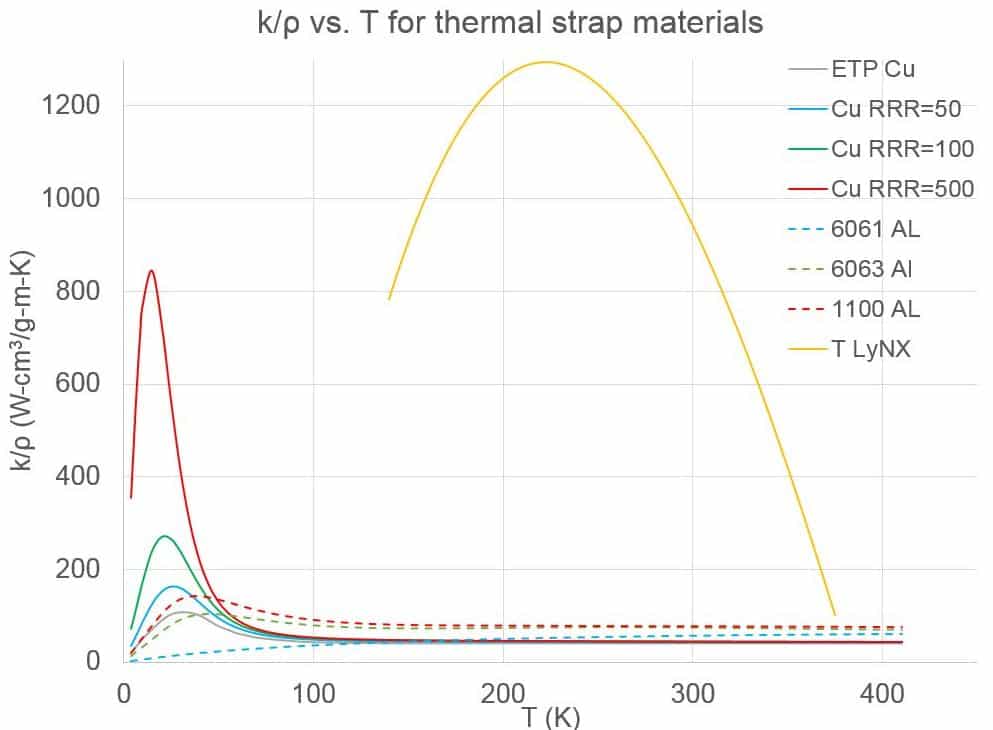

Developed primarily for use in space where mass is critical, Thermal LyNX® graphene thermal strap technology is built upon nanostructured pure carbon that provides better than twice (2x) the thermal conductance to mass ratio compared with any other thermal strap previously developed and available within the marketplace. The graph below shows the temperature dependent thermal conductivity of Thermal LyNX® graphene as compared with copper and aluminum on a standardized mass basis. The huge advantage of Thermal LyNX® peaks at a temperature of around 220 K, where thermal conductivity is 16 times that of aluminum and 27 times that of copper per unit mass.

Temperature Dependent Thermal Conductivity/Density of Thermal LyNX, Copper, and Aluminum

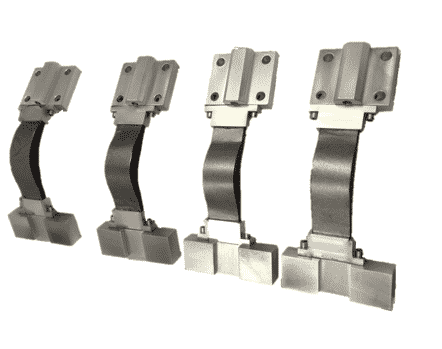

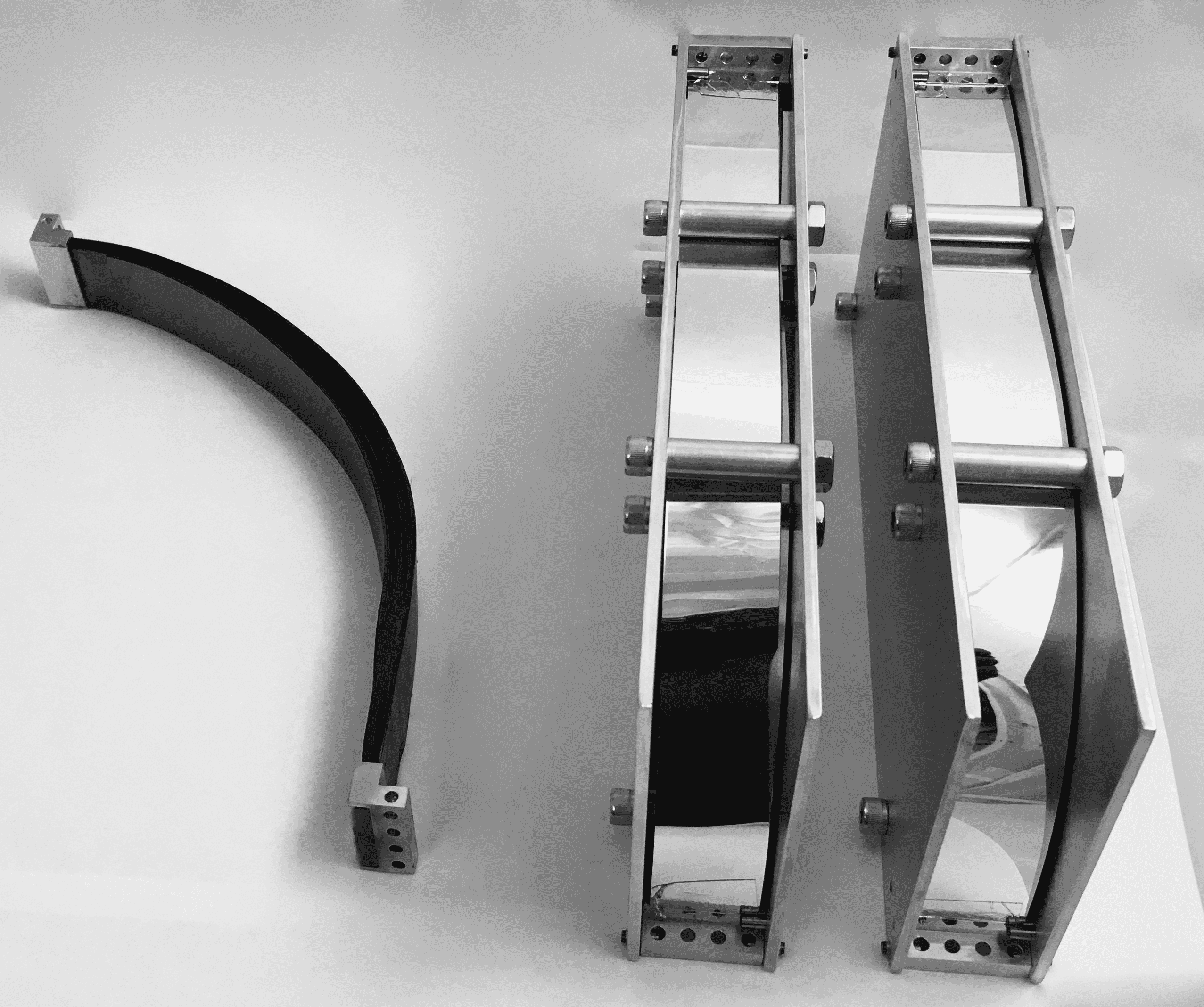

In addition, Thermal LyNX® straps are volumetrically superior with their streamlined configuration and have orders of magnitude greater mechanical flexibility and range of motion than any graphite fiber thermal straps that have been previously used in space systems.

The Durable and Highly Flexible Thermal LyNX®

Carbon Composite End Fittings for Added Mass Reduction

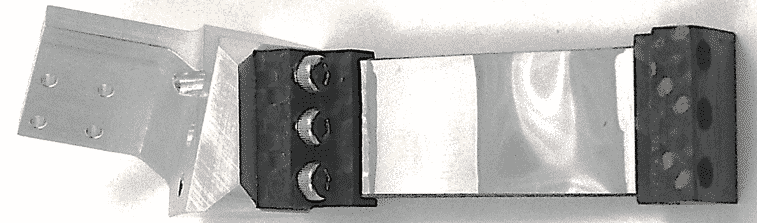

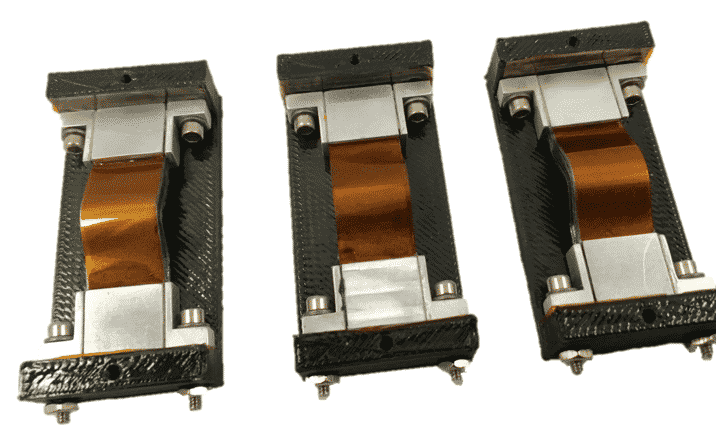

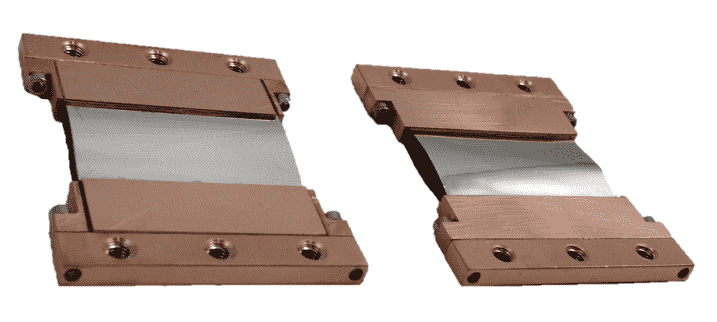

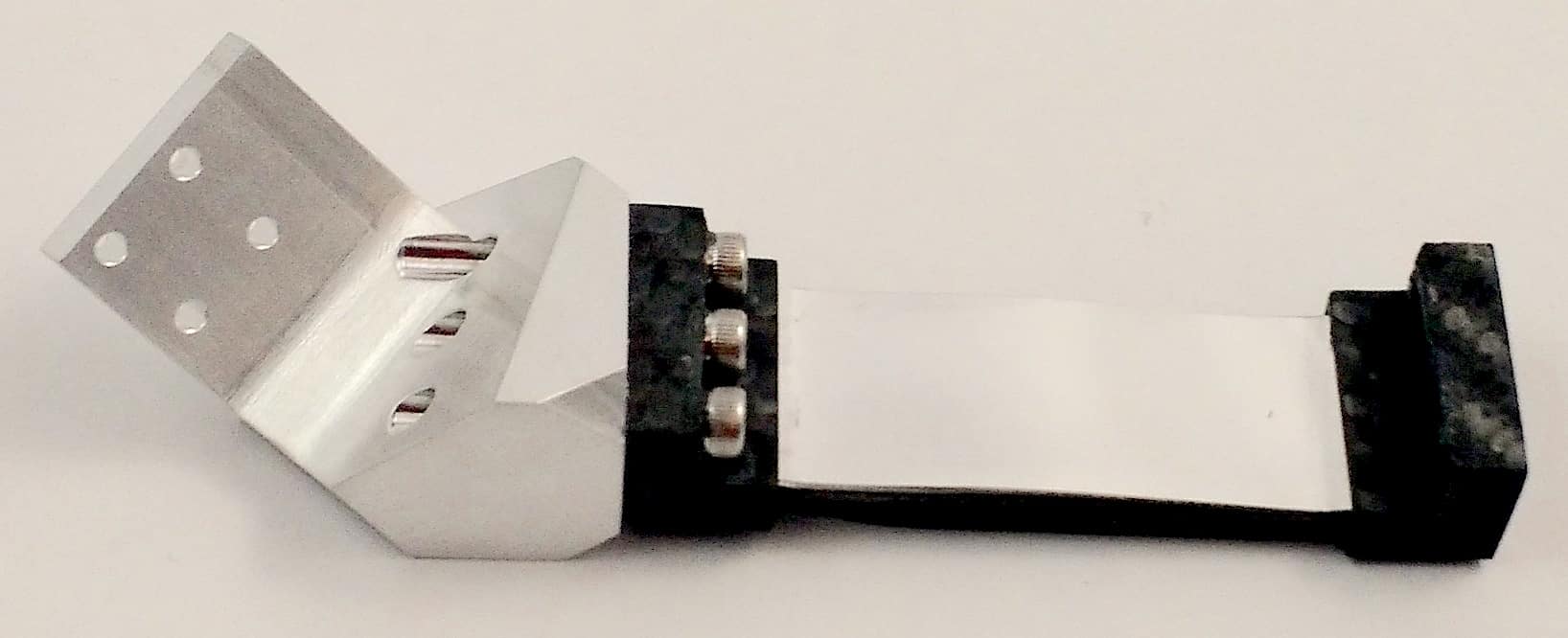

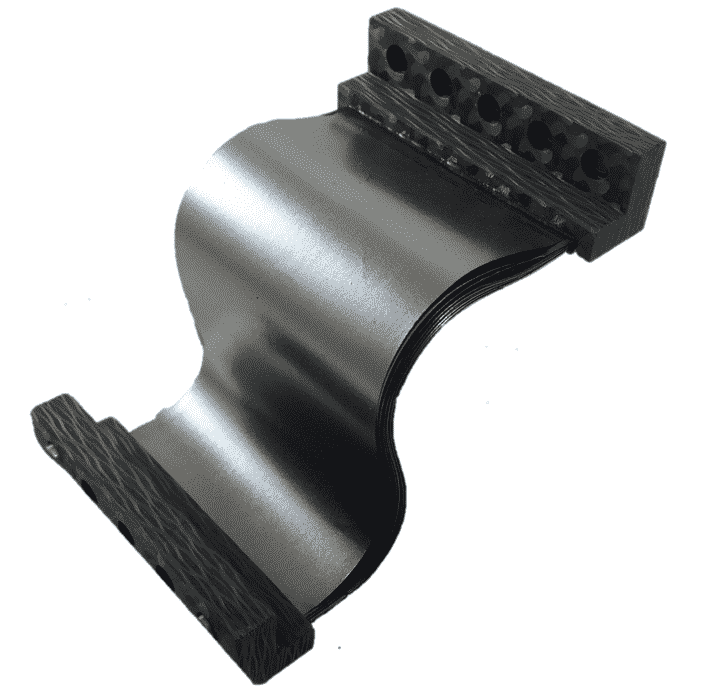

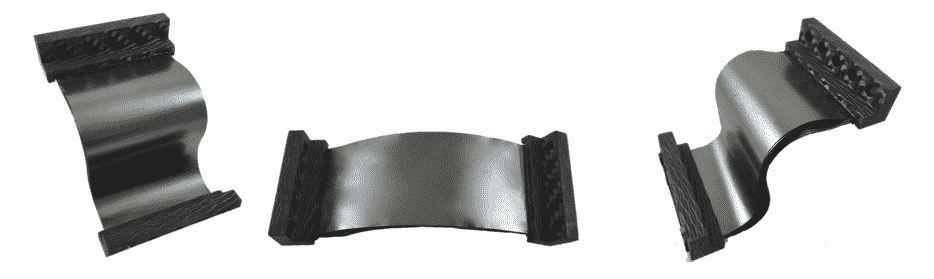

With overall mass efficiency as the primary objective, Thermal LyNX® typically uses high-modulus carbon composite end fittings in conjunction with the extremely-flexible, robust, layered nano-structured graphene material. The end fittings, often referred to as terminals or mounts, can be precisely machined to most any configuration that will enable interfacing to your hardware with either threaded fasteners, adhesives, or by clamping. Precise CNC machining in these end fittings is used to incorporate features such as holes, slots, or pins typically used as alignment or registration provisions, and (standard or locking) threaded inserts to accommodate a complete range of fastener options.

Thermal LyNX Graphene and Carbon Composite Thermal Straps

Higher Thermal Conductivity, More Flexibility, and Lower Cost

There is no need to ever consider the use of brittle, contaminating, less conductive, load- and range-limited graphite fibers in thermal straps again.

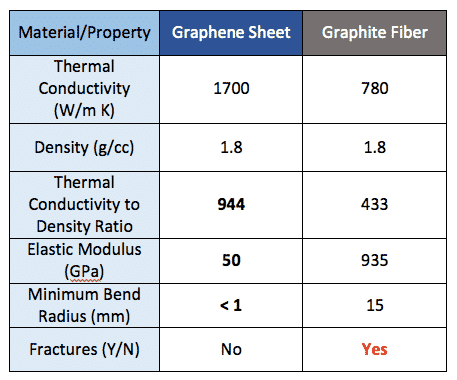

The table below highlights the greatly superior thermal and mechanical performance of Thermal LyNX® when compared to thermal straps made of high-conductivity graphite fiber. Note that the graphene foil used in Thermal LyNX® construction has more than twice the thermal conductivity to density ratio as compared with the best graphite fiber. In addition, the graphene foil modulus is nearly 20 times smaller than that of the fiber, meaning that a strap made in the same configuration will have a stiffness 20 times lower than a graphic fiber thermal strap. Superior material flexibility coupled with highly-adaptive form and lower cost makes Thermal LyNX the best choice available in thermal strap technology.

Graphene sheet is far superior to graphite fiber in every way

NASA Approved Materials

All materials used in the construction of Thermal LyNX® are well below published NASA outgassing limits, making these straps ideal for use in space flight systems. Unlike other carbon straps, there is no threat of particulate contamination because the material does not fracture or splinter as does graphite fiber; therefore, Thermal LyNX® do not need to be encapsulated or encased with any other materials that compromise flexibility, limit range of motion, and introduce temperature limits.

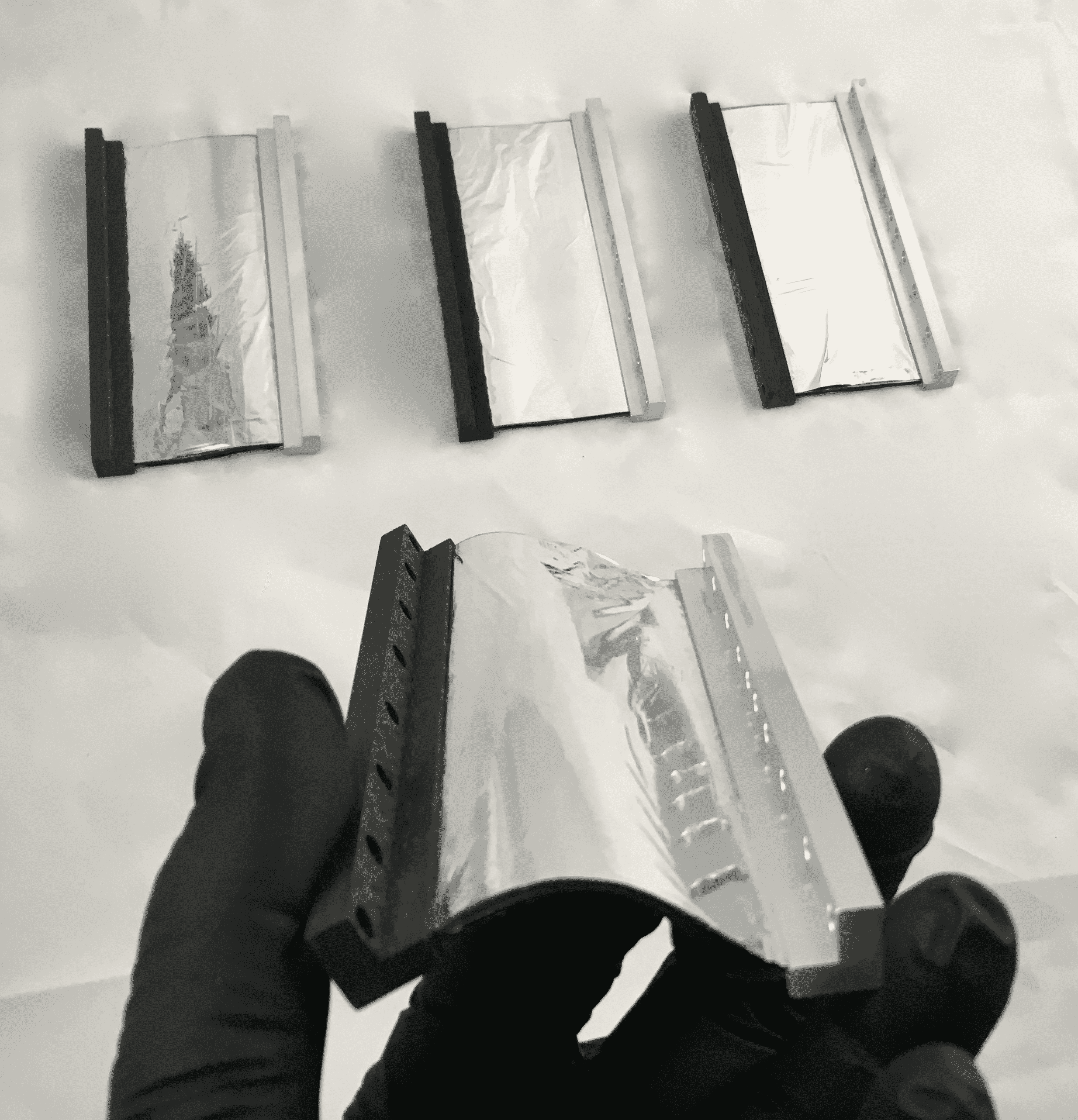

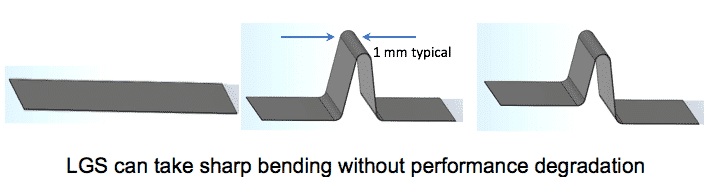

In fact, the layered graphene foil (LGF) material used to fabricate Thermal LyNX®, is so forgiving that it can take sharp bending without any performance degradation whatsoever!

Standard and Custom Configurations Available

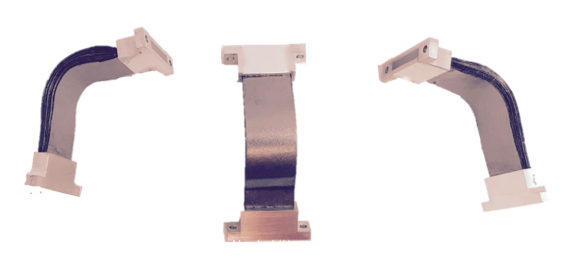

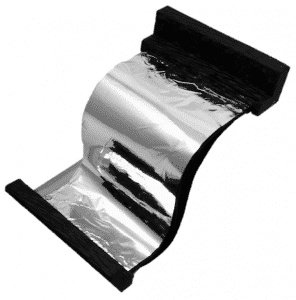

Thermal LyNX with Aluminized Mylar Outer Layers

Thermal LyNX® straps are available in a wide array of configurations from straight to nearly any curvature or twist necessary to bridge the gap across most thermal interfaces and accommodate nearly any range of motion. Typical sizes (length, width) range from millimeters to feet. Aluminized Mylar® (polyester) or Kapton® (polyimide) can be directly integrated with Thermal LyNX® to add another layer of thermal and mechanical protection without compromising mechanical flexibility.

Thermal LyNX® are significantly more robust than any graphite fiber thermal strap and very different from delicate pyrolytic graphite sheet (PGS) and graphene composite sheet thermal straps pedaled by strap vendors that attempt to sell knockoffs.

Call or email Thermal Space Ltd. today if you think your system can benefit from this significant advancement in thermal-strap technology.

.