Stiffness Testing

(Flexibility, Spring Constant)

Hooke’s Law states that the force needed to compress an elastic device such as a spring (or thermal strap) is proportional to the distance, or F = kD, where k is a property of the device and is generally known as the spring constant. For large range motion, k is not necessarily linear; however, by using incremental steps it is possible to “map” the stiffness of a device over a range of deflection. The stiffness of a thermal strap is typically an important parameter in many applications and often must be measured directionally over a range. Further, many thermal straps exhibit hysteretic behavior in the force distance relationship that results from relaxation and repositioning of the individual elements that comprise the flexible portion of the strap. Our test approach is designed to characterize the relevant stiffness behavior of the device being tested.

Thermal-Strap Testing

Thermal-Strap Testing

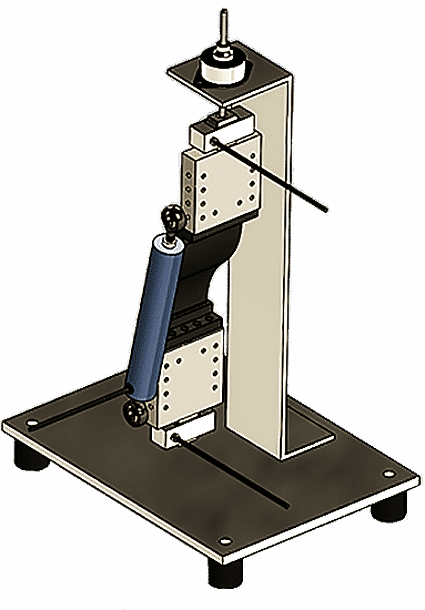

TSL can measure and document the force vs. distance behavior (stiffness) of any thermal strap in each of the three linear axes. Our test equipment for measuring stiffness is quite simple consisting of a stable platform, a moving stage, a deflection sensor and force sensor(s). The general configuration shown (not including automated data recording) is capable of measuring the device stiffness one axis at a time by changing the position of the strap in the fixture. Currently, we are set up to measure stiffness at ambient temperature, but have plans to make these measurements in vacuum and over a temperature range from 80 K to 450 K. Typical maximum deflection is on the order of 10 mm, but by changing sensors, a larger range can be accommodated. The nominal displacement sensor allows for as little as a 0.01 mm incremental measurement so that micro- to macro-scale stiffness can be fully characterized.