Our Packaging and Shipping Protocols

Thermal Space, Ltd. has documented procedures in our AS9100 Compliant Quality Manual (QM) covering product inspection, preservation, packaging and shipping. These standard procedures are essential and followed in every program – unless more stringent controls are specified. Assembly documents are maintained with the finished product as it moves through inspection, packaging and shipping. Generally, our process to create an authorized shipment entails several well-controlled steps, as detailed below.

Quality Control Guides Our Process

We’ve completed your thermal system or components and now we need to make sure the hardware arrives to you in perfect condition. We do not take this aspect of the project lightly. Generally, our packaging and shipment protocols are configured as described below:

After initial inspection and test of a finished product, the hardware is segregated within our client-specific pre-delivery area, to protect it from damage and foreign objects debris (FOD).

When it’s time to deliver the product, a configuration audit is performed to ensure the hardware conforms to the latest version of the procurement documents. Then, a final review is conducted to ensure all testing and inspections have been carried out, the product conforms as specified, has been documented accordingly, and that the product is ready for shipment and receipt on your end. Any required certificates of conformance (CoC) and performance (CoP) are generated, verified, and signed. These documents are included in each shipment, as part of our standard quality assurance (QA) package.

The product then undergoes final cleaning, per TSL standard procedure or project-specific requirements. Each part or subassembly is individually packaged in an oxygen-barrier bag and purged with dry nitrogen gas, then heat sealed. If specified by the customer, the bag can be constructed from an anti-static material. Moreover, the bag can be evacuated and shipped under soft vacuum, instead of a nitrogen gas purge.

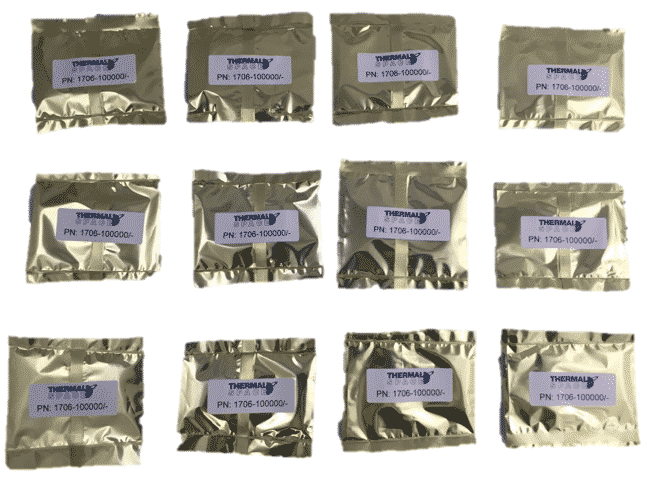

Thermal Straps are Double Bagged and Purged with Dry Nitrogen.

If multiple products are shipped at the same time, we will typically group the individual packages into a larger oxygen-barrier bag, and purge and seal (or evacuate) the outer bag in the same fashion as the as the individual bags. This provides an additional protective barrier during shipping and makes a conveniently transported unit on the receiving end. Desiccant packs are sometimes incorporated within the outer bag, to further protect the parts in the event that the outer packaging seal is somehow compromised.

The bagged parts are typically packaged within a stiff cardboard box. Sometimes, a hard-sided plastic case or metal box is specified or warranted for shock sensitive hardware. All products are completely cushioned with packing materials or foam, to further ensure no damage is incurred during shipping. Any hard-sided shipping container can be equipped with shock indicators that trigger if an out of range shock event is encountered during shipping.

Oxygen Barrier Bags Assure Your Hardware is Clean and Ready to Integrate.

TSL typically uses FedEx 1- and 2-day delivery services, but other carriers and services are readily available in our area.