Thermal straps are sometimes referred to as thermal links, flexible thermal links, heat straps, flexible thermal straps, thermal shunts, conductive links, flexible heat conductors, or flexible thermal path.

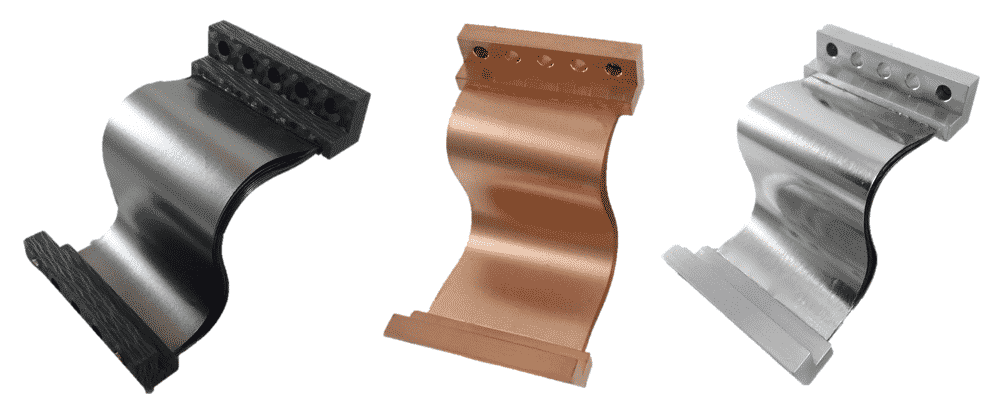

Carbon | Copper | Aluminum

Thermal Straps Made from Graphene, Copper, and Aluminum Foils are Just Some of Our Thermal Products.

Highest Performance Thermal Straps for All Applications

Our thermal strap products are simple and robust, yet provide the highest performance available. That is what sets us apart from everyone else. We have the original heritage for all the thermal straps that we manufacture from copper cable straps that go back decades to our unique Thermal LyNX® straps. Each and every thermal strap is designed, fabricated, inspected, and tested right here in Boulder, Colorado!

Unmatched Thermal Strap Experience

Whether you need a single thermal strap or thousands, we are equipped to handle your project. From the highest performance flexible thermal links available anywhere to simple and cost effective options, the Thermal Space Team has unmatched experience from decades of thermal strap design, fabrication, and testing for both commercial and space systems.

We are the original thermal strap designers for space, defense, and scientific systems.

We are the original thermal strap designers for space, defense, and scientific systems.

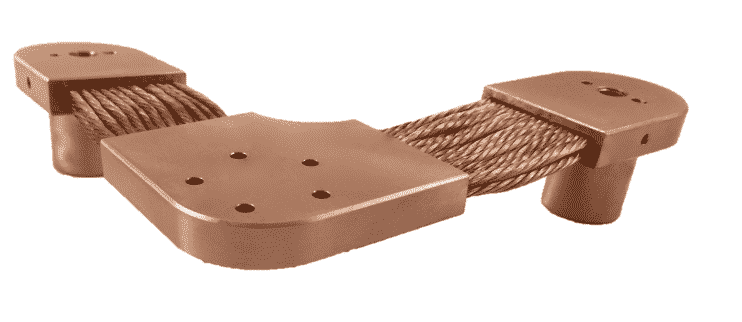

Most thermal strap offerings in the market today have traceability back to our engineering team including aluminum foil, copper foil, copper cable (sometimes referred to as rope or braid), graphite fiber, and graphene-based thermal straps. Our engineers have qualified many thermal straps for space and military use, including the first graphite fiber thermal straps used for space flight on programs such as NASA’s Orion and JAXA’s ASTRO-H.

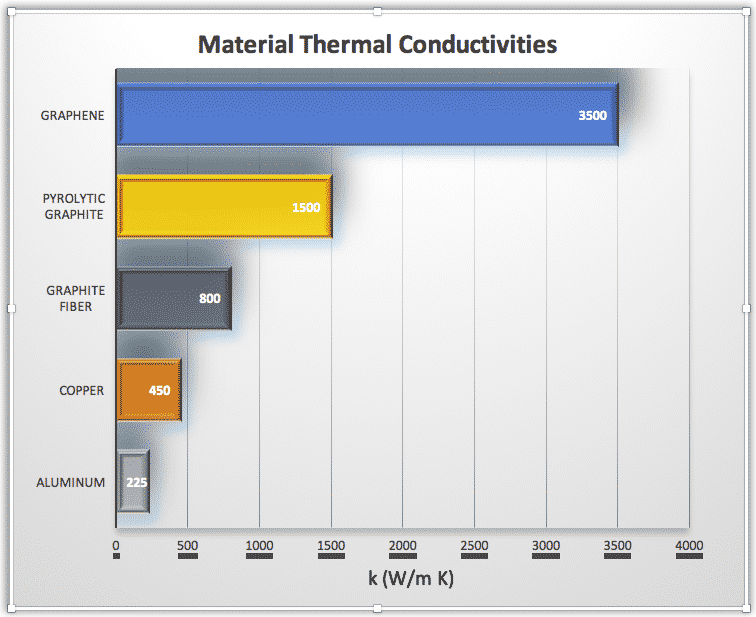

In continuing to advance thermal strap technology, Thermal Space developed and now offers Thermal LyNX® graphene-based thermal straps that are superior in every performance category as compared to brittle and stiff graphite fiber thermal straps. In fact, in our Blog you can read why graphite fiber has been a marginal material for use in thermal straps and how it desperately needed to be replaced.

Thermal Straps for Use in Advanced Thermal Management Systems

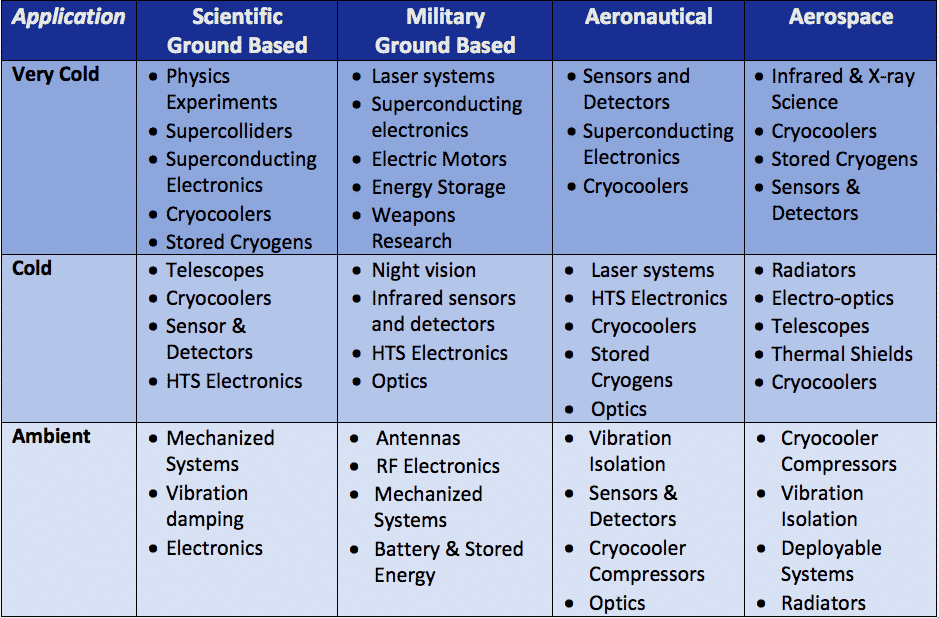

Thermal straps are often a critical component in thermal management systems, perhaps playing a more significant role in space-based systems where conduction and radiation are dominant mechanisms for heat transport.

Thermal straps are often used when heat (thermal energy) needs to be transferred and a large temperature gradient cannot be tolerated between two or more discrete locations (interfaces) that are either:

- positionally fixed but not well defined relative to each other

- positionally fixed and well defined relative to each other, but it is necessary to decouple transported mechanical energy (vibration, shock)

- not always positionally fixed relative to one another over time

Most times these conditions are the result of mechanical tolerance uncertainties and accumulations, post-assembly movement due to material thermal contractions, mechanized systems that are designed to move, induced transient mechanical loads (such as a rocket launch), or mechanical disturbances from an active component or subsystem that are detrimental if not adequately attenuated. The tendency for any of these conditions leads to a wide variety of potential applications for thermal straps in ground, aeronautical, and aerospace systems. Some of the more common thermal strap applications are contained in the table below.

Simple and Precision Heat Straps

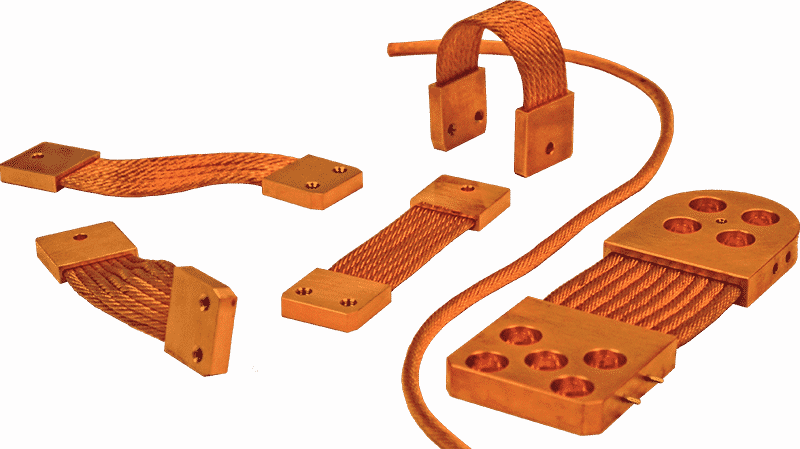

Thermal straps in various forms, from simple or crudely constructed linkages to high-precision components with well-defined interfaces, have been used to manage heat flow in many applications from the commercial electronics and automotive industries to our most advanced scientific, military, defense, and space systems. Sometimes a thermal strap may be as basic as a coiled tube, bunch of wires, or stack of foils without a solid attachment terminal. In other configurations, the terminal or end fitting is welded, brazed, soldered, bonded, or otherwise attached to the flexible section of the strap to provide more direct and robust mounting capability. The appropriate configuration for any thermal strap really depends upon what thermal management system it is going to be integrated with.

Our focus at TSL is high-precision, high-capacity and thermally-optimized straps to enable performance in the most demanding applications. Our engineering team has been involved with the design, fabrication and test of precision thermal straps for more than 25 years, including the first documented use of a layered aluminum foil thermal strap for use in space dubbed the S-link. (“Design and Verification of Stirling Cooler Interfaces Suitable for Long-Lifetime, Spaceborne Sensor Systems”). While we are highly experienced, our thermal strap products are cost effective and provide the best value in the market because they always meet or exceed the design criteria.

Thermal Strap Material Systems

Metal Thermal Straps

Traditionally, most thermal straps have been constructed from either aluminum or copper due to the inherently high thermal conductivity, low relative material cost, and durable mechanical properties of these metals. Metal straps are almost always made from either copper wires, copper foils, or aluminum foils. They are most useful in low-temperature applications (below 100 K or -180°C) and are sometimes used at warmer temperatures when mass is not a significant performance driver. In the past twenty-five years, there has been development and commercialization of carbon-based materials that have lower density and higher thermal conductivity than copper or aluminum, making for thermal straps that are especially attractive for use is aerospace and aeronautical applications.

Carbon, Graphite, or Graphene Thermal Straps

High conductivity carbon materials (in the form of pyrolytic graphite or graphene) have been commercially available in both fiber and sheet configurations over the past several decades. Graphite fiber thermal straps have been used in space applications despite the inherent limitations (lower thermal conductivity, brittle, expensive, limited suppliers, limited bending, contamination threat, fabrication challenges, handling and integration issues, etc.) of the fiber material itself. So, while pitch-based graphite fiber was a tolerable material choice for thermal straps decades ago, research and development in graphene and nanotechnology has led to commercially available carbon materials that have game changing thermal and mechanical properties as compared to pitch-based fibers. The chart below shows room temperature thermal conductivity of materials commonly used in thermal strap construction. If density is taken into consideration, there is an even more dramatic benefit to the carbon-based materials.

Room temperature thermal conductivities of typical thermal strap materials

Where thermal conductance to mass ratio is critical, such as in most space systems, our graphene-based Thermal LyNX® product is the most advanced and highest performance thermal strap available in the market.

Our Thermal Strap Heritage

The engineering staff at Thermal Space Ltd. has decades of experience designing, fabricating, and testing thermal straps for aerospace and defense applications, including full space qualification. Our heritage with state-of-the-art thermal straps began when our CEO was a young engineer and part of a multi-disciplined team tasked with designing a thermally efficient means to interface mechanical cryocoolers into a staged superfluid helium cryostat. Due to the very limited mechanical load that could be tolerated at the cryocooler cold tip interface, an extremely flexible and thermally efficient link (strap) was created unlike anything previously built. That early work was published in several professional journals and is still referenced today in the Spacecraft Thermal Control Handbook (Section 14). As needs evolved, so did thermal strap technology and the engineering team at Thermal Space has been at the forefront in the development of consistent and higher performance thermal strap products and their application to diverse markets.

For Aerospace, Defense, Scientific and Other Commercial Systems

We specialize in custom thermal straps to meet your high-performance needs, but also work with laboratories and academic institutions where maybe the limits don’t need to be pushed quite as hard. Whatever your application, our thermal straps are designed to move your heat between the source and the rejection point with a prescribed degree of mechanical flexibility. We offer complete and highly cost-competetive services to design, analyze, fabricate, and test our thermal products to completely satisfy and verify your requirements. Our team and facilities are second to none.

Understanding Your Needs

Typical challenges facing the thermal-strap designer are balancing requirements that often include other controlled characteristics beyond just thermal conductance and flexibility. These other requirements may include: 4C-PURE OFHC Copper Thermal Straps serve many markets.

Getting You the Best Service and Products

That’s what it’s all about. At Thermal Space Ltd. (TSL), we have the experience and tools necessary to provide you with the optimum thermal straps for your application. Moreover, while we know how to build the finest and most reliable thermal straps in the marketplace, we understand the success of hardware itself is the result of an efficient and well developed set of engineering capabilities to specify, design, fabricate and qualify a product to exacting standards. There are several manufactures that are just interested in selling components and are not interested in the engineering or science behind each design. We recognize that not every application requires a custom thermal strap and that there are budgeted component costs. In these cases, please feel free to contact us as well. We are always happy to recommend reputable suppliers of quality thermal hardware when your needs and our capabilities don’t match up.

It’s Your System and Our Reputation

As thermal-system engineers, we specialize in understanding your system boundaries beyond just our own products. The more difficult your thermal strap requirements are to achieve, the more interested we are in speaking with you. When you call TSL, you won’t get a salesman trying to steer you to a certain product with a prescribed configuration. Our engineering team is front-end oriented, to work with you to fully understand and document all your requirements prior to embarking on any design effort. We care about the success of your project and you have the right to know the relevant experience level of the person or people you speak with.

Avoid any confusion: you will never need to consider more than a few straightforward thermal strap options to get the performance required for any application.

Beware those that distort thermal strap complexity along side self-proclaimed expertise, excessive materials and configuration options, with unsubstantiated cost and performance claims promoted through a marketing and sales pitch. Such claims are simply an attempt to create the illusion of knowledge and expertise, when in fact no technical base exists to adequately represent an authentically engineered product. Always ask to speak with an experienced engineer to get a true sense of technical breath and capabilities.

Contact Thermal Space Ltd. and get all your questions answered. Ask for our FREE no obligation consultation, to see if TSL is the right company with the right solutions for you.