You Can Bookmark This Page Directly at www.Thermal-Straps.com

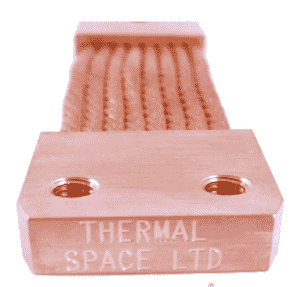

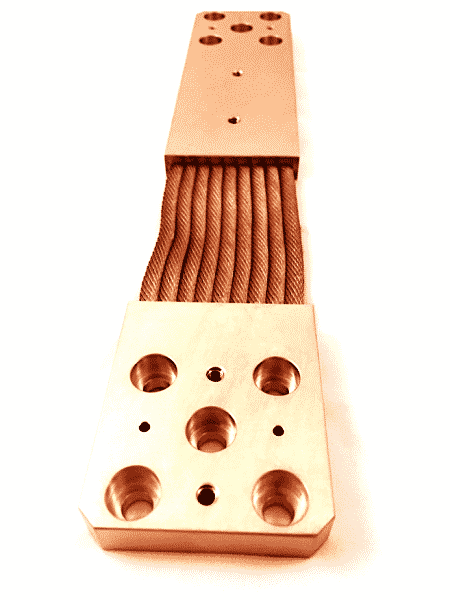

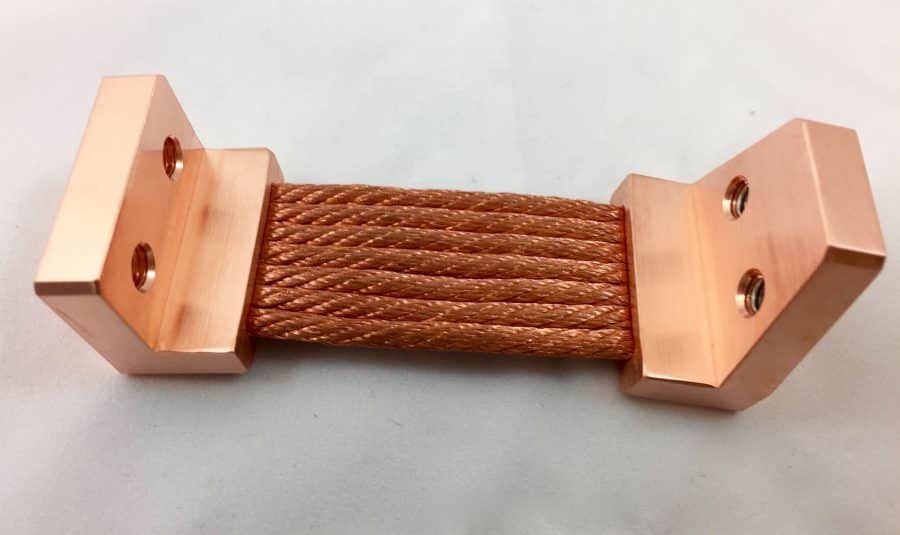

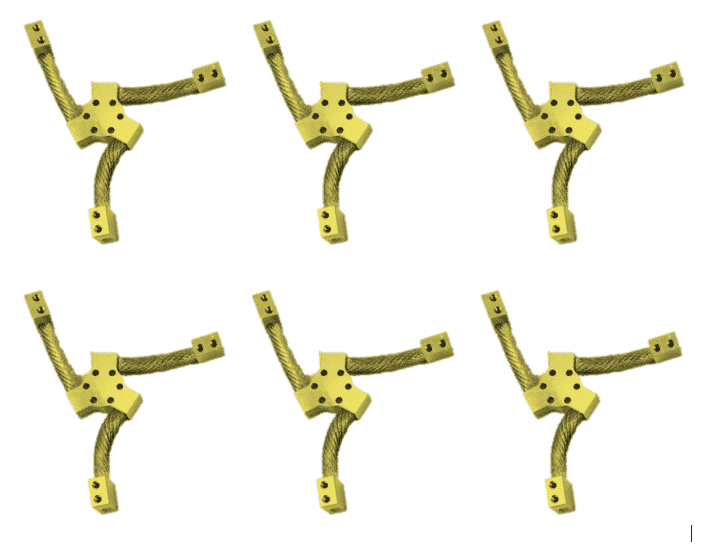

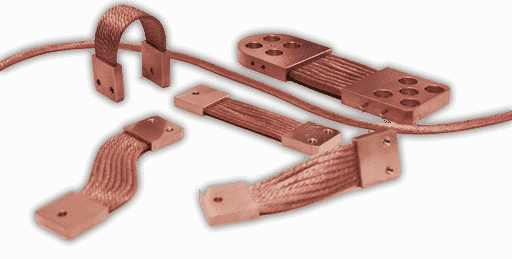

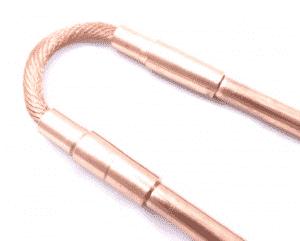

Cabled Copper Thermal Straps

The Solderless Flexible Thermal Links

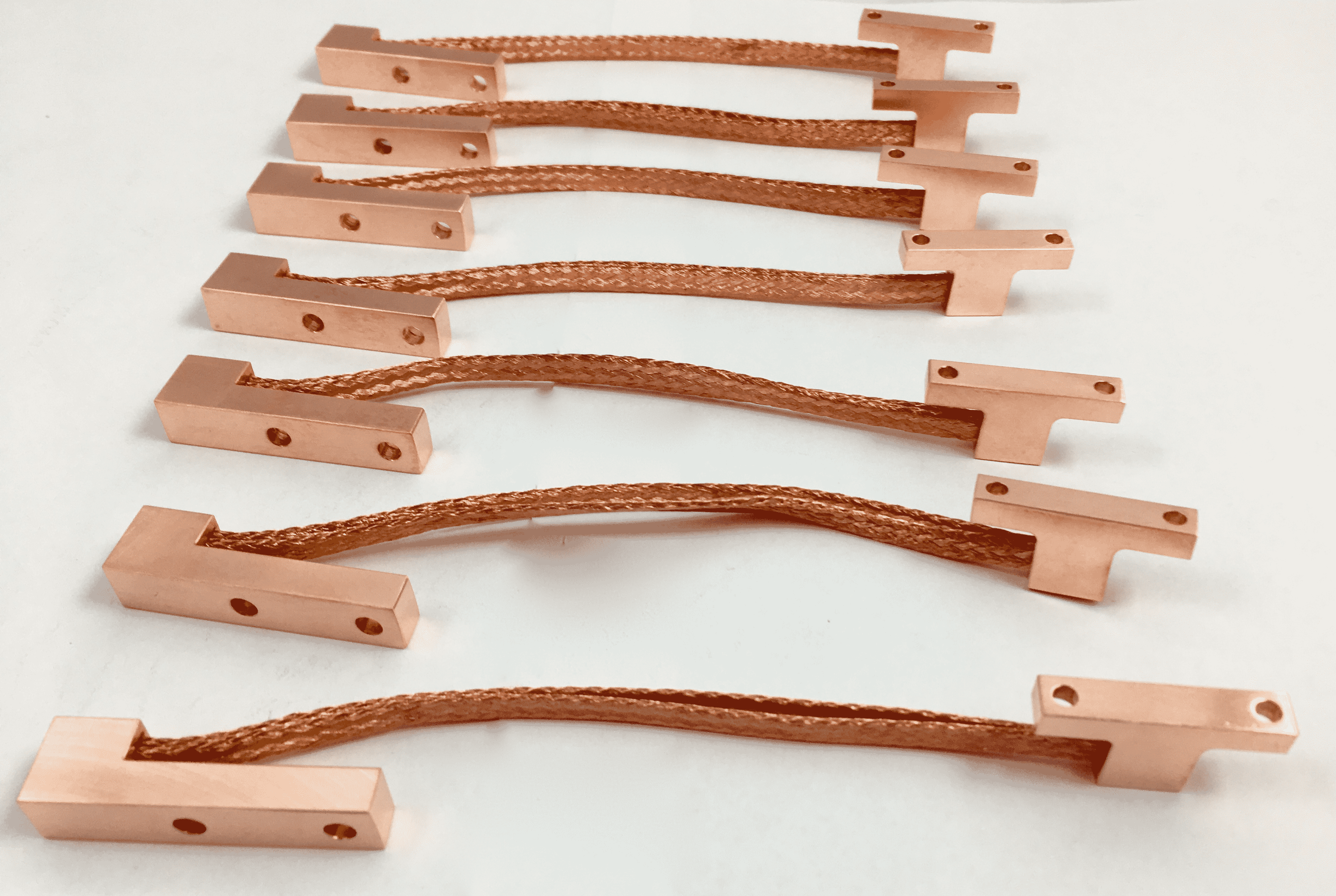

Our simplest and most cost effective copper thermal straps are built right here in Boulder, CO from bundled and cabled high-purity copper wire strands that are then captured into solid copper end fittings or terminals. Our fabrication process is original, established and proven over time and uses no solders, adhesives, or other means of attachment…..just 100 percent OFHC copper. Manufacturing of these straps is still handled by the same people that developed the process decades ago and that is now emulated by others claiming it as their own.

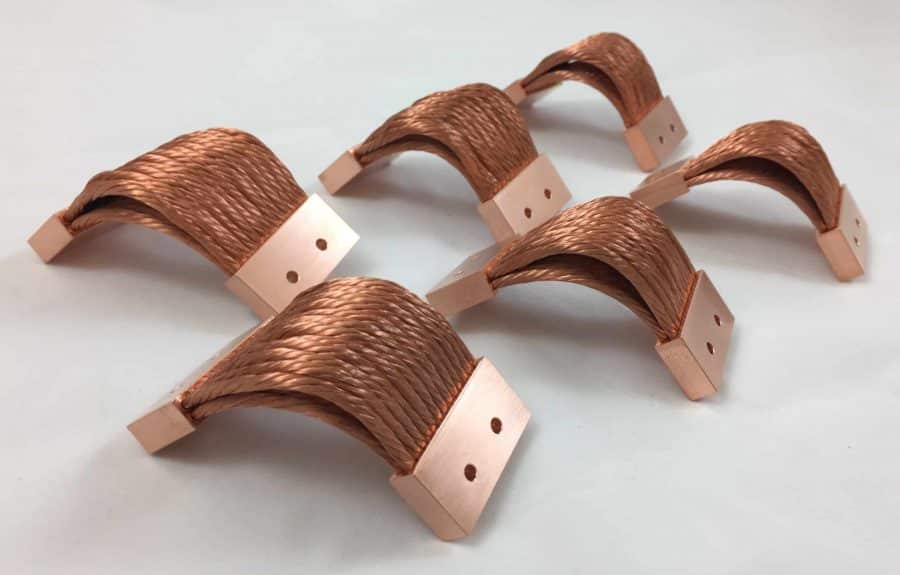

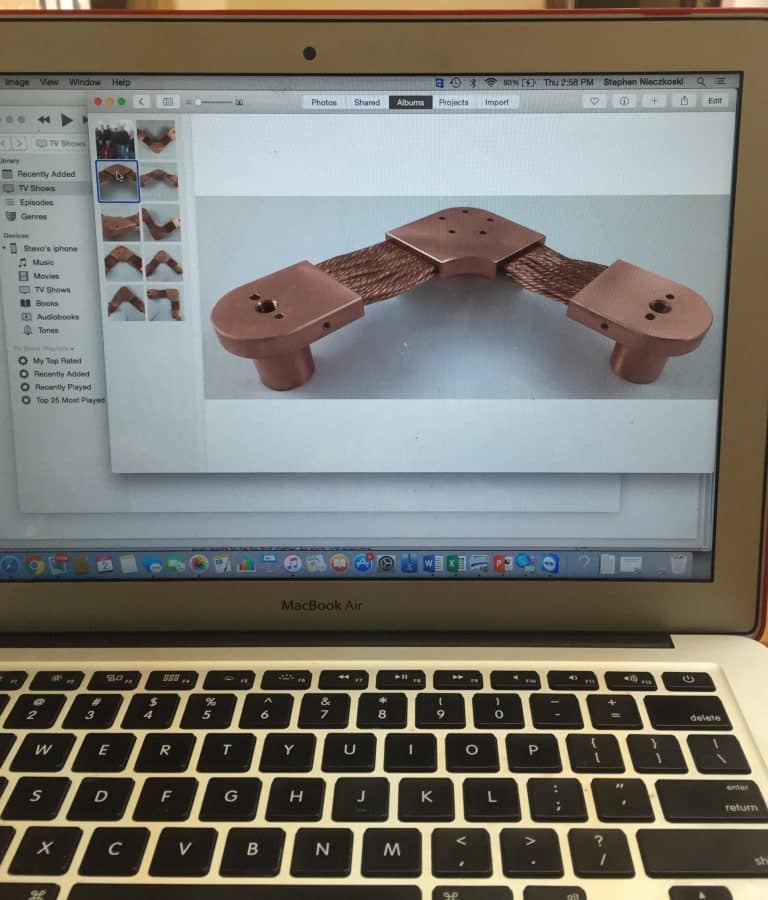

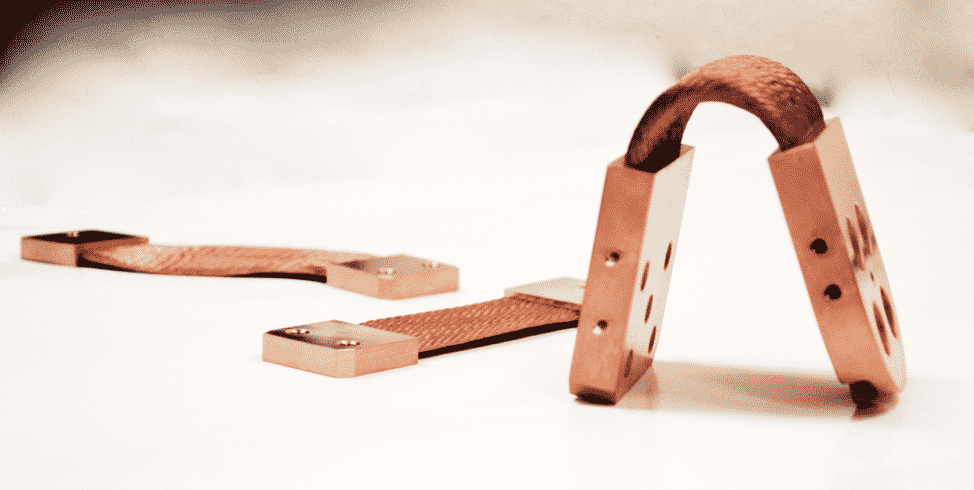

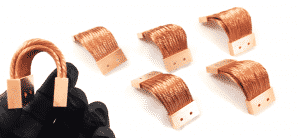

Sometimes rather than copper cable, we use copper braid in our straps to intentionally bias mechanical flexibility in one or more axis.

Both cable and braided copper strands can be referred to as rope. In most thermal strap applications, it is the combination of thermal conductance and mechanical flexibility that are important. We design our straps using materials, configurations, and a fabrication process that maximizes both thermal and mechanical performance.

The 4C-PURE™ Thermal Strap Advantage

4C-PURE™ and 4C-PURE-CRYO™ Straps are Thermal Space Ltd.’s product line of pure copper thermal straps fabricated from 100% oxygen-free copper. We use no fillers, binders, solders, adhesives, non-metallic coatings, or other materials in the the fabrication of these straps.

The -CRYO series straps are intended for low-temperature service and include material certifications for copper purity and the option for cryogenic testing to verify superior performance in cold applications. By fabricating thermal straps from only high-purity copper, we provide the maximum performance metal strap product available in the market today.

Highest Quality Copper Thermal Straps Available – 4CP Thermal Straps

Often Copied… But Never Reproduced

Our Conductive Compliant Cabled Copper (4C) – PURE (100% OFHC copper) thermal straps are fabricated to exacting standards using common and well-established fabrication techniques that assure high quality, superior performance, and repeatability. While we understand that nearly anyone can produce a thermal strap, the cost and performance advantages that we bring to our clients are the direct result of many decades experience in developing thermal straps as well as other thermal component and systems hardware for the aerospace and defense industries. Specifically, the cost and performance advantages in our copper thermal straps are achieved through:

- rapid concept development – once we have your requirements we will typically have a concept to you within a day. Need help capturing your requirements? That’s not a problem; we routinely help our clients with this.

- accurate modeling and analysis to predict performance – our predictive empirical models developed through many years of thermal engineering experience will assure that your strap will conform to your minimum requirements.

- concept to fabrication drawings – we move from concept to production phases at an unequaled pace and we involve you in the process. All assembly drawings are client approved prior to any fabrication.

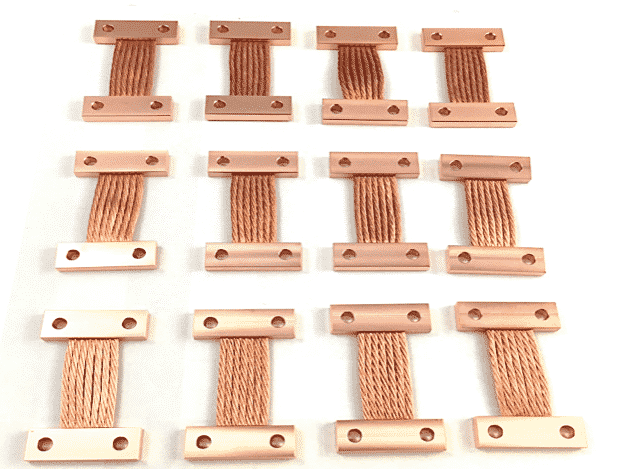

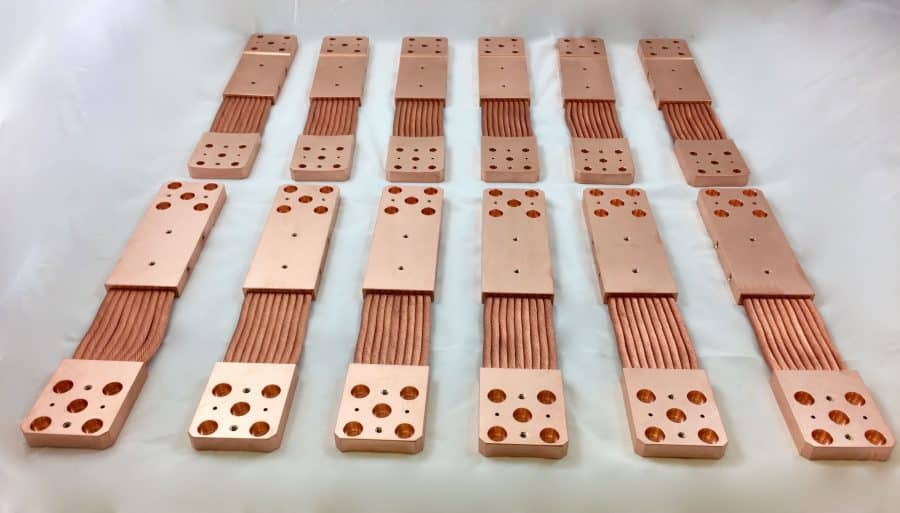

- fabrication repeatability – because our concept, fabrication, and verification processes are well defined, consistent, and documented, our thermal straps perform with a high-degree of predictably and repeatability.

- post-fabrication cleaning – we deliver straps that are ready for integration out of the package; our cleaning process is based upon understanding manufacturing and material surface chemistry to achieve the most effective removal of potential contaminants.

- mechanical and thermal performance verification testing– whatever test qualifications are required to prove the performance of your thermal straps, we are equipped and experienced to meet those needs, including cryogenic testing.

Unlike some companies that vend only thermal straps, you can rest assured that with Thermal Space Ltd., real engineering principles, knowledge, and experience are behind each design and reflected in the optimum performance of each unit.

OFHC Copper( C101, C10100) Material Selection

OFHC Copper( C101, C10100) Material Selection

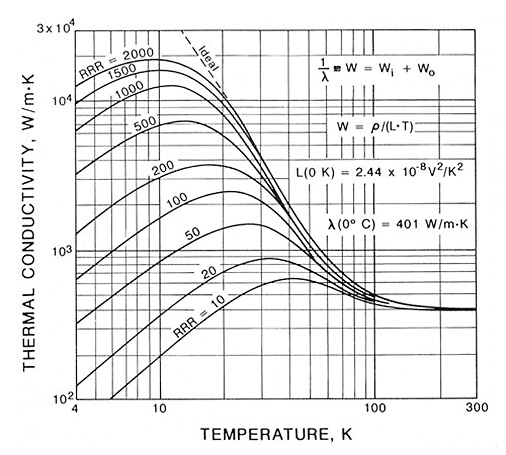

Our 4C-PURE™ Thermal Straps use entirely oxygen-free high-conductivity (OFHC) copper in the construction. OFHC copper (99.99% purity) provides superior low-temperature thermal performance compared to other commercially available purities and is typically not a cost driver, even if low-temperature service is not required. The figure below shows the temperature dependent thermal conductivity of copper as a function of temperature and different purity levels as defined by the residual resistivity ratio (RRR).

You can read more about RRR in copper here: http://www.jim.or.jp/journal/e/pdf3/38/08/714.pdf

(Graph courtesy of www.copper.org)

OFHC copper typically has a RRR between 100 and 200 and thus the large increase in thermal conductivity from warm to cold temperatures makes this high-purity copper the preferred material selection in our thermal straps.

OFHC copper typically has a RRR between 100 and 200 and thus the large increase in thermal conductivity from warm to cold temperatures makes this high-purity copper the preferred material selection in our thermal straps.

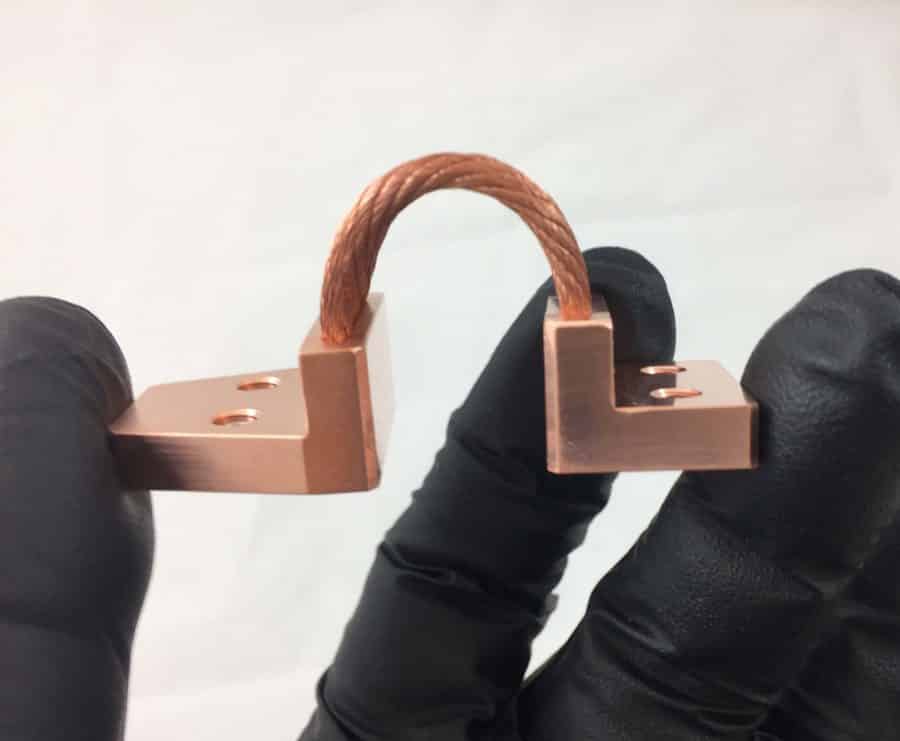

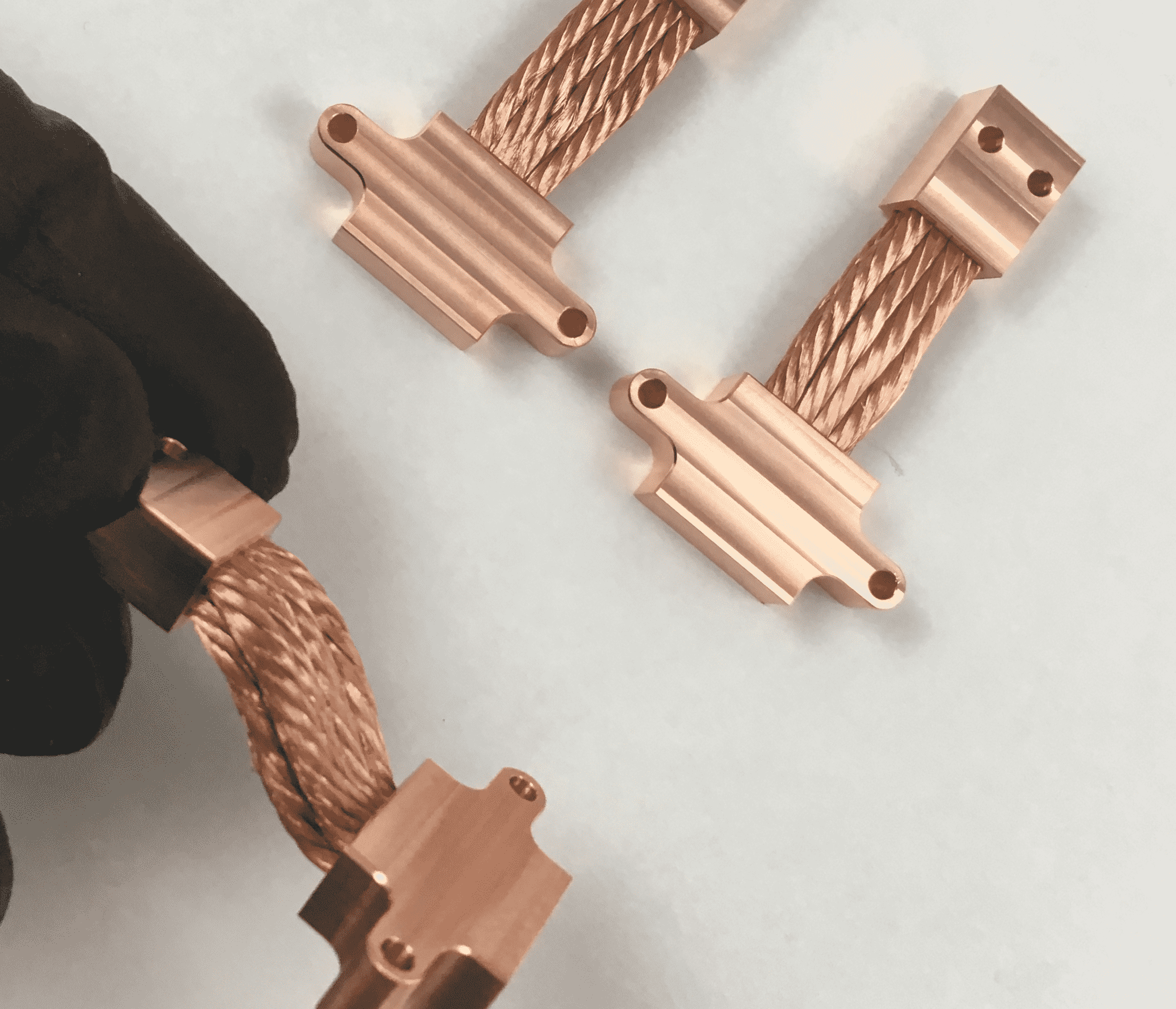

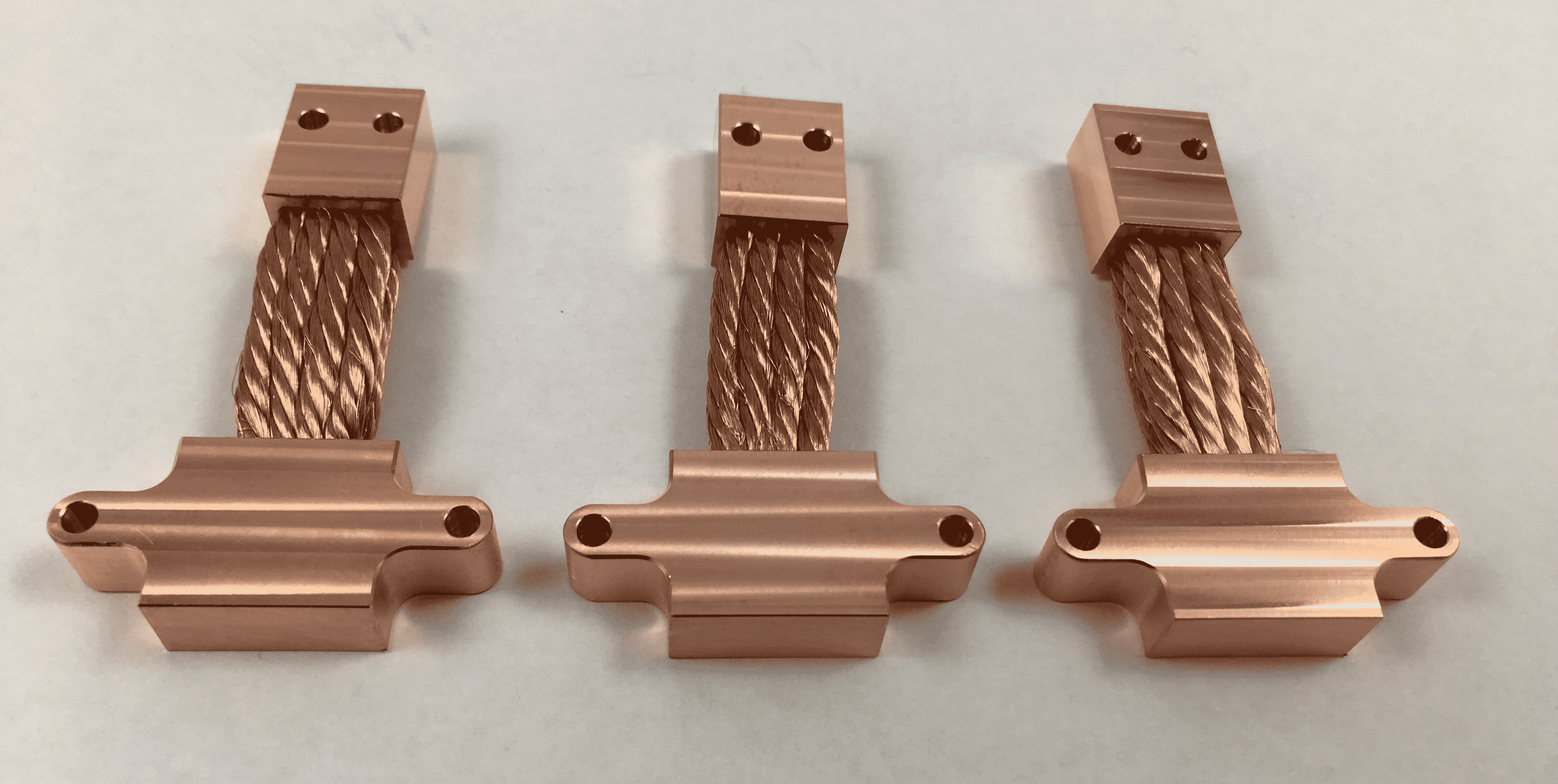

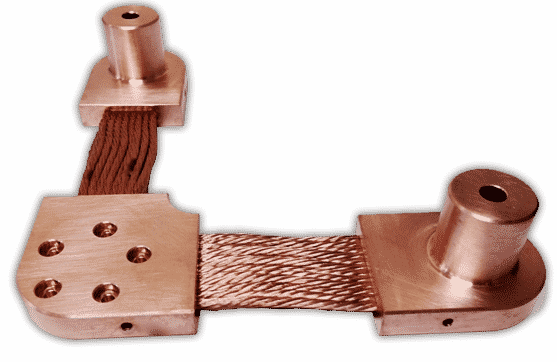

Cryocooler Thermal Strap Interfaces

Our engineers have been involved with developing and interfacing cryocoolers or cryogenic refrigerators in cooling systems for 20+ years. We understand both the thermal and mechanical issues necessary to support the integration of both regenerative cryocoolers (such as Pulse Tube and Stirling) and recuperative cryocoolers ( such as Reverse-Brayton) in sensitive instrument and optical systems.

Flexible thermal interfaces with cryocoolers routinely use our 4C-PURE-CRYO™ thermal straps.

Cryocooler Interface Thermal Strap Assembly Provides More Than 1 W/K Thermal Conductance

We offer many cryocooler thermal strap configurations to support both common and custom cryocooler heat transfer applications, both on the cold side and at the warm compressor interface. Our copper thermal straps commonly used in cryocooler interfacing are higher performance and less expensive than any competitor’s standard or catalog listed thermal straps.

4C-PURE™ Thermal Straps are designed to move the most heat and provide exceptional utility in most thermal management applications. Where weight is a dominant parameter, our carbon-based Thermal LyNX® straps are the optimum choice, excelling at thermal conductance on a weight basis.

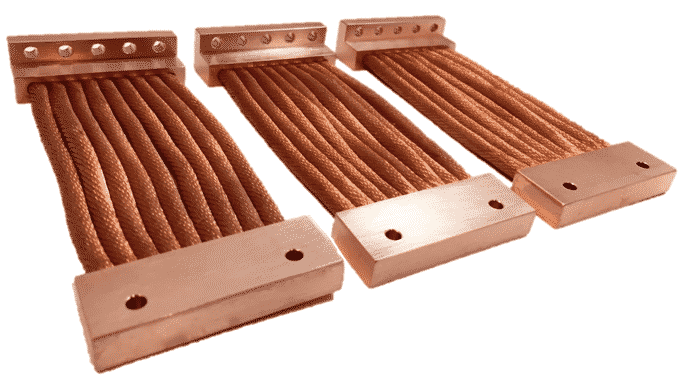

Highest Flexibility and Thermal Conductivity

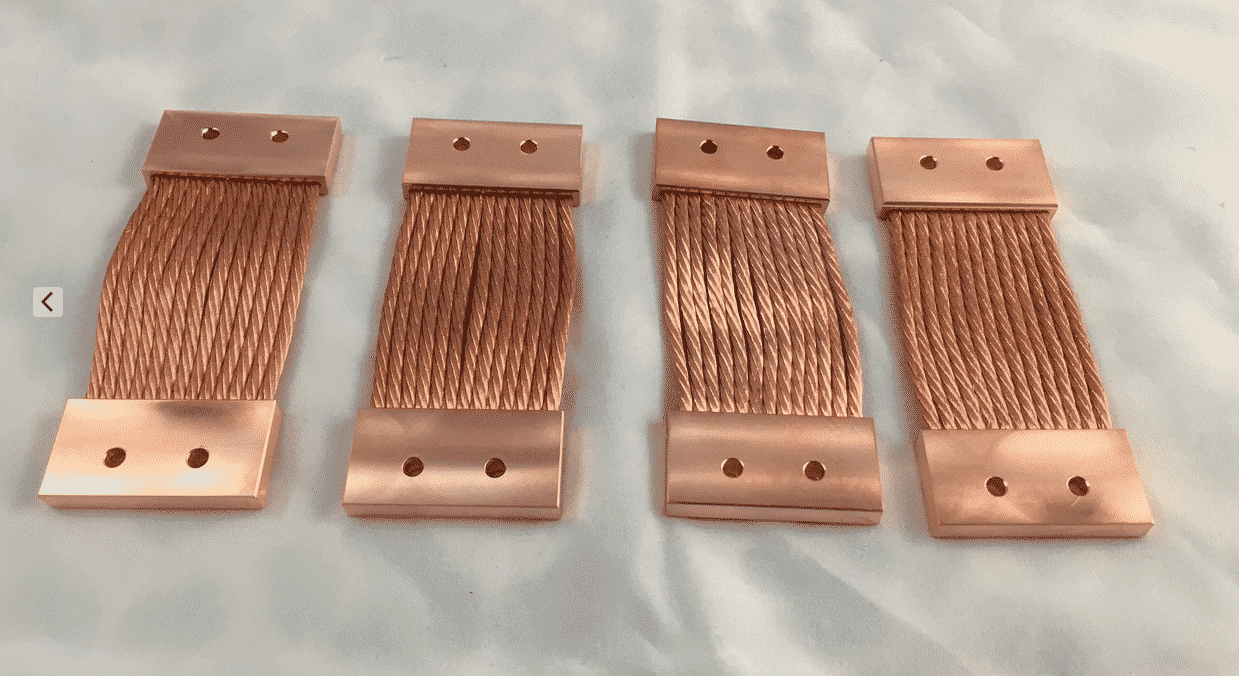

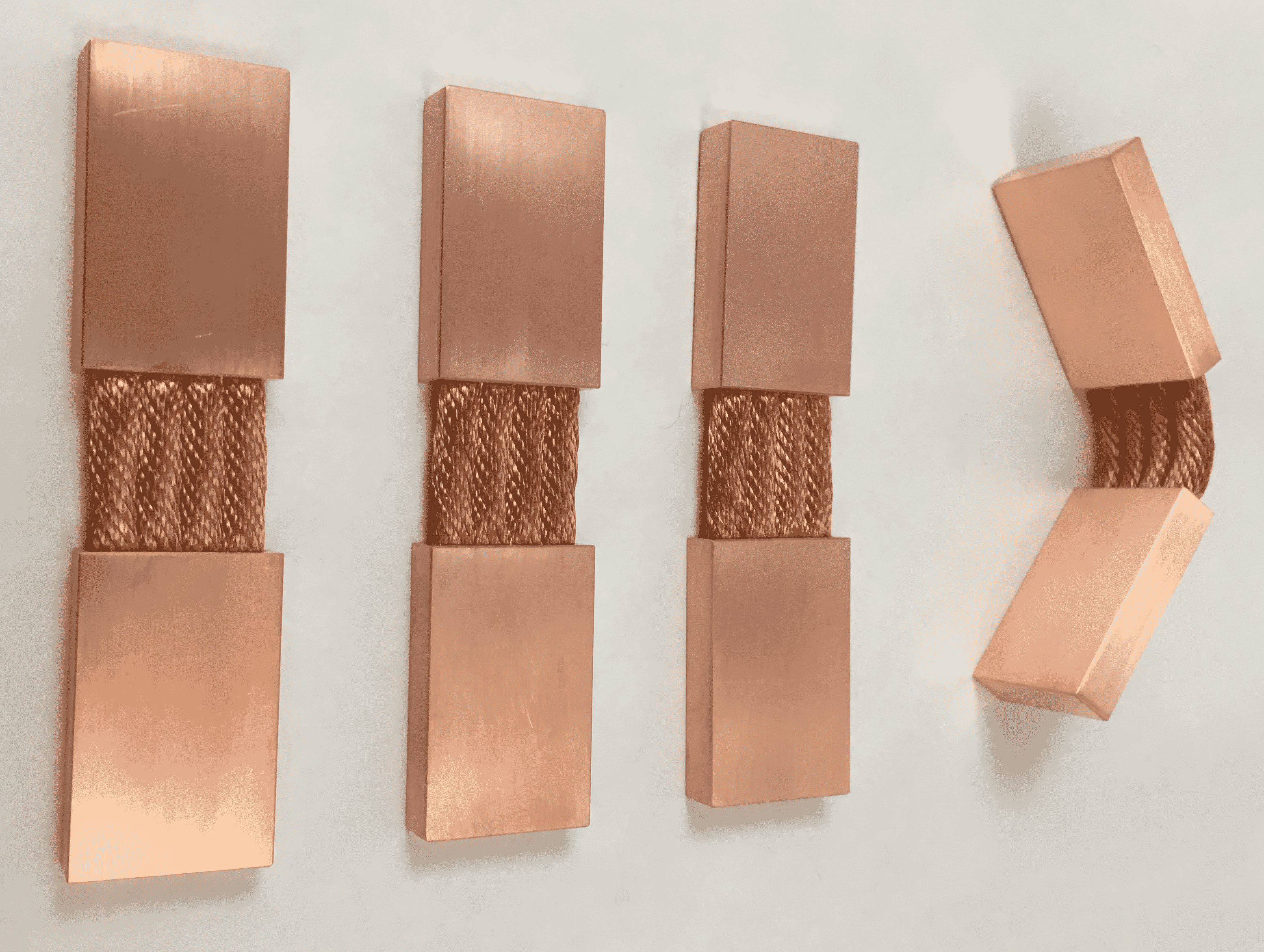

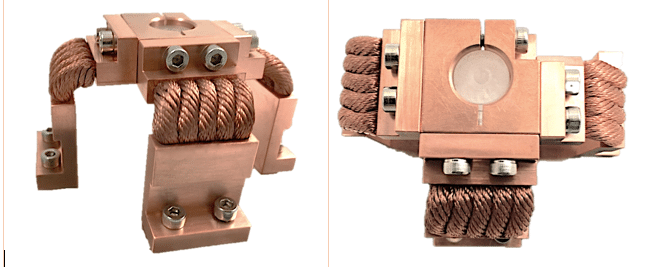

A distinguishing feature of our 4C-PURE™ Thermal Straps is that we work with many flexible copper cable and braid configurations. We design and build your thermal straps from the cable or braid configuration that provides the optimum combination of mechanical, thermal, and economic parameters to meet your needs.

In general, a cable configuration of equivalent gauge (cross section) that is comprised of more and smaller diameter wires has greater mechanical flexibility than one configured from fewer and larger diameter wires. The stranding and bundling of wires and then cabling the bundles into unique configurations and equivalent gauges are the control parameters used to tune stiffness, bend radius, and range of motion in a thermal strap.

However, as with many things, there is a trade-off between thermal performance and mechanical flexibility. Thermal efficiency between the strap cables and terminals has a small dependence on the number and diameter of copper wires used in the strap construction. Therefore, we have developed comprehensive analysis tools that can be used to predict performance in any unique thermal strap design.

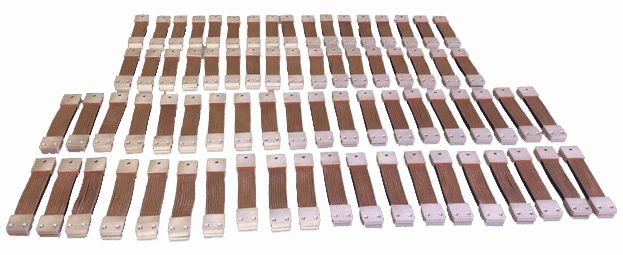

These braided OFHC copper thermal straps were designed for high rotational flexibility with limited motion in the lateral direction.

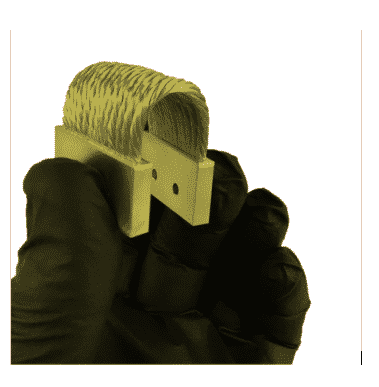

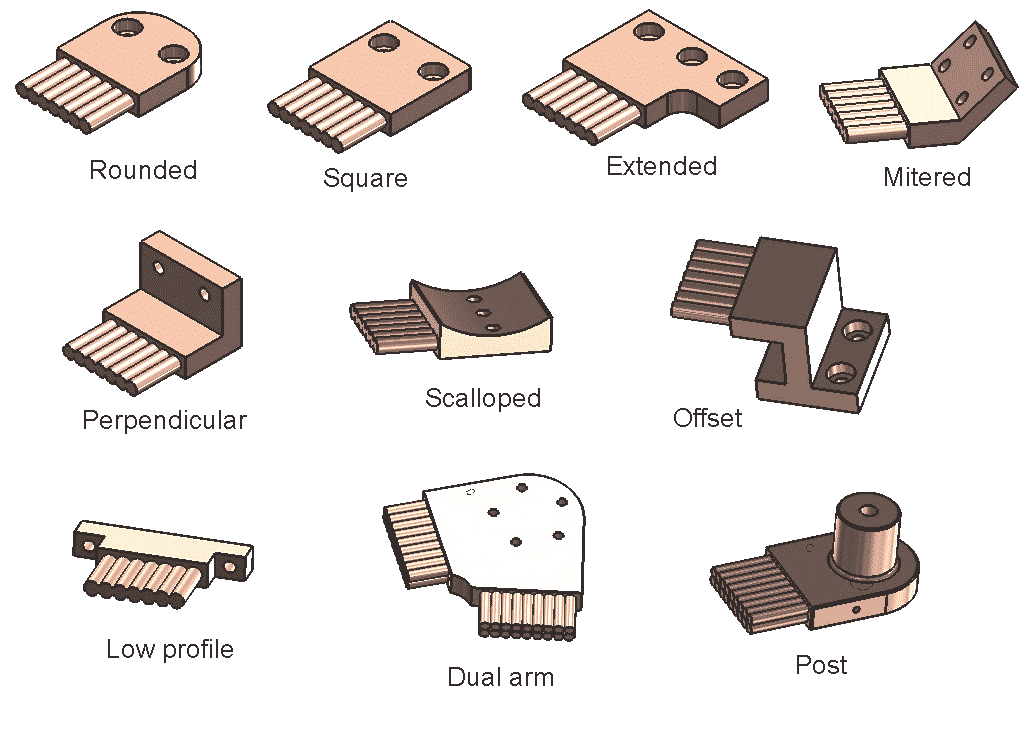

Standard Terminal (End-Fitting) Configurations

Depending on project needs, your thermal interfacing specification may result in either standard or custom thermal strap terminal designs. In either case, we work closely with you to determine the optimum configuration(s) that meet your specific requirements while being compatible with our 4C-PURE™ manufacturing processes. Some of the more common terminal designs we work with are shown below.

Standard geometries typically result in lower-cost copper thermal straps, but many times custom terminal configurations are requested, especially when the mechanical design of a project is fairly mature.

Standard geometries typically result in lower-cost copper thermal straps, but many times custom terminal configurations are requested, especially when the mechanical design of a project is fairly mature.

With our fabrication process, we can readily control terminal features such as hole diameter and location to 0.001-inch or better. Whether your straps are deigned to be bolted, clamped, or bonded we make sure you get the most efficient performance possible.

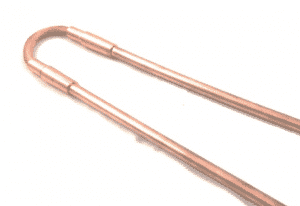

Hybrid Thermal Straps

Thermal Space can directly integrate our thermal straps with other heat transfer components such as heat pipes and vapor chambers. While heat pipes are a very efficient means to move heat, they have inherent limitations associated with thermal capacity, mechanical flexibility, orientation, and operating temperature. By directly integrating our copper cable thermal strap technology with these devices, the best performance attributes of both flexibility and long-distance heat transport can be realized. If you are using or have considered using heat pipes or vapor chambers in your thermal management system and are concerned with any of the potential limitations, we have a solution.

Thermal Strap Metallization

Some thermal strap applications may benefit from metal coatings for thermal control and surface passivation. Thermal Space offers several proven metallization options for our copper thermal straps including Gold (Au), Silver (Ag), Nickel (Ni), and Tin (Sn). We have many years experience and can steer you clear from generic plating processes that can cause a host of issues in metal coated thermal components. Our gold coated thermal straps have the lowest surface emittance available anywhere.

Interface Thermal Resistance is Important

An important consideration in any thermal strap design is whether the required thermal conductance is inclusive or independent of the thermal interface resistances between the strap terminals and the mounting interfaces. We will ask this question very early on because the answer can influence any adequate thermal strap design. There are several reliable, repeatable, and thermally efficient interfacing options available that we can recommend, if there in not a preferred approach already defined.

With our 4C-PURE-CRYO™ thermal straps, we provide guidelines that help maintain efficient thermal interfacing throughout temperature cycling as well as methods to minimize any parasitic thermal coupling between a cold thermal strap and warmer surroundings.

How Thermal Space Provides the Complete Package

Whether you are just at the information gathering stage or quickly need a well-defined copper thermal strap, it’s likely we have your optimum solution.

We specialize in providing comprehensive thermal engineering solutions for our clients. From front-end concept development to the back-end verification and integration efforts, we deliver.

- Specification and Statement of Work development services

- Need large thermal strap quantities? We have the the capacity to fabricate quantities in the thousands of units

- Read more about our standard and custom cleaning protocols here (Click Here)

- Full level verification services including thermal testing, static stiffness testing, dynamic stiffness testing, mechanical vibration and shock testing, tensile testing, thermal cycling, and electrical grounding verification.

See Our Packaging and Shipping Protocols (Click Here) >>

Professional Products and Services

For Flight and Non-Flight Systems…..be sure that you are getting the best technology available in the market today…….from Qualified Aerospace Thermal Engineers!